Entering a New Era of Smart Manufacturing

Introducing SRP-FEC220 Solution for Machine Monitoring & Optimization

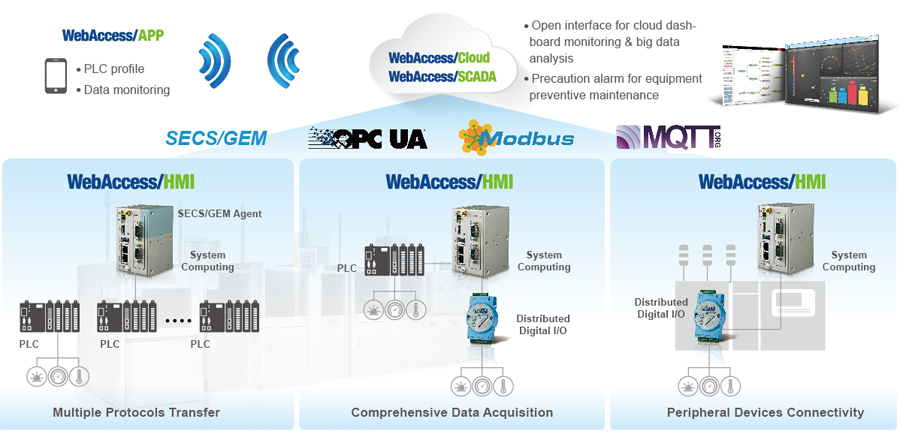

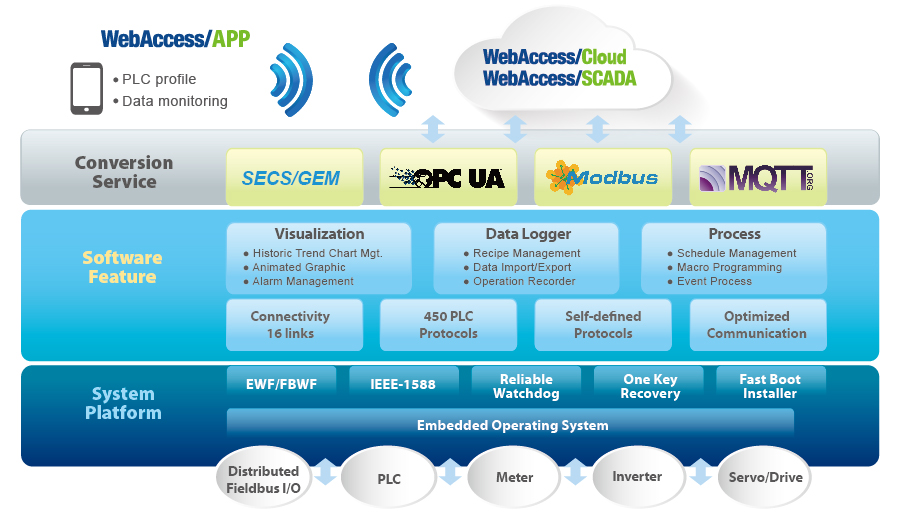

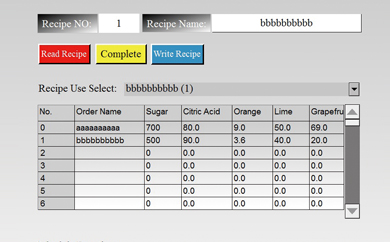

This Solution Ready Platform allows users to easily acquire 100% of equipment data through 450 PLC drivers, self-defined communication protocols and a distributed digital I/O module. Equipment data is available for OT/IT system integration via Modbus/ OPC UA/ MQTT with visible production information, optimized production profiles and more.

Key Advantages/Features

100% Data Acquistion

Supports 450 PLC communication drivers and self-defined protocol to completely acquire controller status, temperature, humidity and other sensor data.

Flexible Protocols Conversion

Greatly shortens engineering time through intuitive UI setting to rapidly covert protocols for a max. of 15 different branded PLCs simultaneously.

Easily Connect OT and IT

Supports Modbus / OPC UA/ MQTT connection to SCADA/ MES system to optimize production efficiency.

Solution-Ready-Platform Package

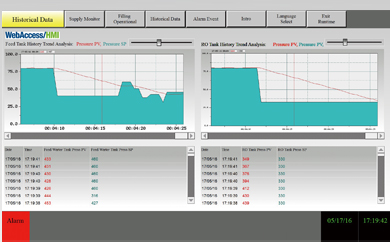

WebAccess/HMI Runtime Software

Preinstalled WebAccess/HMI Rumtime 1500 tags

UNO-2271G-E23AE

Intel® Atom™ E3815 1.46 GHz Pocket-Size DIN-Rail PC, 4GB RAM, 32G eMMC Storage, Microsoft® Windows Embedded 7 Pro

ADAM-6060-CE

6-ch Digital Input and 6-ch Power Relay Modbus TCP Module

Software Architecture and Key Design Features

HMI Design Features

Animated dashboard

- Dynamic numerical value display

- Pipeline & dynamic flow diagram

- Bar chart/ histogram

- Rich automation device icon library

Alarm

- Active alarm message

- Alarm by email

- Alarm history

- Alarm history export (Excel CSV)

History

- Historical trend chart

- Historical table for search

- Historical data export (Excel CSV)

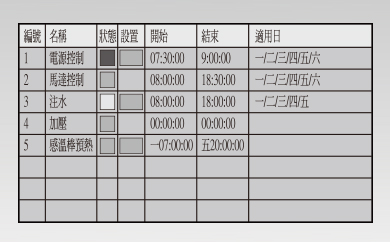

Schedule

- Calendar chart

- Weekly event schedule

- Pre-schedule process parameter

Application Scenario

How the Equipment Connectivity Works in Facotry

Pain Points of Global Manufacturers

Data in Black Box

To optimize equipment performance and reliability, engineering teams always make improvements through machine operation data analysis, temperature monitoring, or power consumption. However, data is sometimes contradictory due to the sensors, meters, or PLC controllers being limited in connectivity and different devices from different vendors each having their own proprietary protocols.

High Wall of Communication

Proprietary communications obstructing machinery data integration usually require knowledge of driver development and comprehensive coding effort to complete protocol transfer.

Infeasible for Analysis

Advanced data analysis is always done by IT systems with powerful computational capabilities. Nevertheless, open communications such as Modbus/ MQTT/ OPC are required for bridging devices at the OT level and system analysis at the IT level.

See What Will Happen…

Extend Equipment Lifespan:

Increase the value of legacy equipment with multiple protocols conversion.

Digitize Manufacturing Information:

Improve manufacturing efficiency by real-time production monitoring, machine status diagnosis.