Advantech's Edge-To-Cloud Solution Powered by WISE-PaaS Creates an AI Equipment Monitoring and Diagnosis Cloud Platform for Steel Plants

8/13/2019

An internationally renowned steel company located in Taiwan introduced the AI value-added equipment diagnostics edge-to-cloud solution of Advantech WISE-PaaS.Through the collaboration of cloud platform, big data analytics, and AI technology, aims to reduce production line downtime, improve the service life of the equipment, and promote the function of automated remote diagnosis and preventive maintenance.

Fault diagnosis in traditional factories passively fixes equipment by relying on senior maintenance personnel to locate problems and schedule maintenance when they arise. When production lines stop due to equipment failure, enterprises suffer considerable losses. Even when subsequent repair is fast, these losses cannot be fully eliminated.

With this in mind, many companies plan to build equipment diagnosis cloud platforms in hopes that administrators can become familiar with the operational status of all equipment so that the necessary treatment and containment of problems can be performed prior to failure. In addition, by analyzing historical data to detect the condition of the equipment, lifespans can be extended.

An internationally renowned steel company located in Taiwan provides one of these cases. The company observed that there was considerable variation in the production line equipment located in harsh environments and exposed to abnormal conditions. Thus, the equipment monitoring and diagnosis cloud project began in hopes of using a cloud platform, big data analytics, and AI technology to flexibly address abnormal situations and improve production and management efficiency.

The steel company prudently decided that the solution provided by Advantech covered the ground, the edge, and the cloud, and had relatively complete content and flexibility. This was convenient for the company in carrying out secondary development in the future to superimpose its own service energy onto the system. Advantech's IoT.SENSE (IoT Solution Enabling Services) team, which was responsible for technical support, had a high degree of mastery of the system. Advantech's was selected to construct an equipment monitoring and diagnosis private cloud platform for the demonstration production line.

Specifically, the steel company outlined five goals for the project:

- establish a standardized data uploading mechanism to improve the diversity and compatibility of data access.

- plan machine learning standard operating procedures to improve the accuracy of equipment diagnosis.

- import visual dashboards to improve data interpretation.

- import smart edge computing technology to improve the immediacy of alarms.

- import modular software and hardware architecture to improve system scalability.

An AI model life cycle management mechanism based on WISE-PaaS:

Perfect integration of equipment monitoring and management

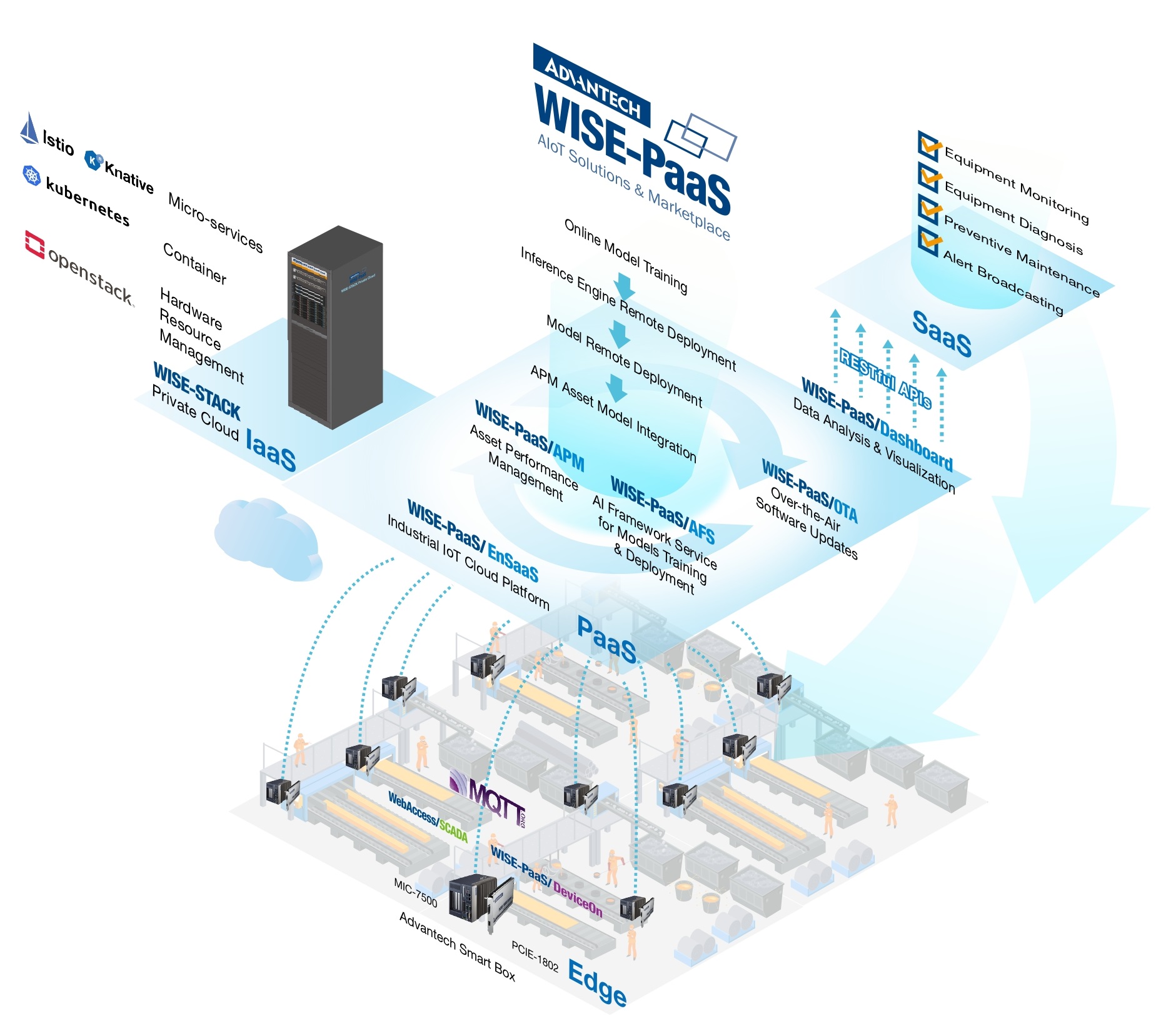

Based on those goals, the steel company planned three sub-architectures for the equipment monitoring private cloud. With Advantech’s Smart Machine Box (SMB) as the core, edge intelligence undertook tasks such as data acquisition and ground computing. The smart machine box was powered by an MIC-7500 industrial computer with an 8-channel high-precision data capture card: the PCIE-1802. Secondly, IaaS was based on Advantech's WISE-STACK-300 private cloud system.

The crucial PaaS part was built on WISE-IoTSuite/EnSaaS, the PaaS service of Advantech WISE-PaaS Industrial IoT cloud platform. The steel company used a number of services, including dashboard creation through the WISE-PaaS/Dashboard, to provide different visualization interfaces for different groups of people such as on-site operators, data modelers, and system operators. WebAccess/SCADA and WISE-PaaS/DeviceOn were used to centrally manage the ground and edge devices and to actively send push alerts when abnormal incidents occurred. By using WISE-PaaS/APM to establish equipment templates and management configurations, users quickly expanded to multiple production lines or plant areas and set event alert logic and report logic for each device, production line, and plant area. Online AI models were developed and trained through WISE-PaaS/AFS and deployed to Edge devices with the AFS Inference Engine. WISE-PaaS/OTA was enabled to meet remote software update management requirements.

Through edge intelligence, IaaS, and PaaS operation, state detection, preventive maintenance, signal stream display, and push alerts were formed, creating an AI value-added equipment diagnostics cloud solution. This project started with a cold rolling mill covering hundreds of devices. Phase 0 introduced the solution to one device in order to verify whether WISE-PaaS could achieve the desired monitoring effect. In phase 1, the solution was deployed to 300 test points to verify system scalability. Once the verification was successful, subsequent copying could be completed quickly. By partnering with Advantech, the steel company completed the above-mentioned process. The next step will be expanding from 300 test points to other upstream and downstream production lines to give full play to the flexibility of the system.

It is worth mentioning that this project had a co-creation effect. On the one hand, it helped the steel company build an independent and controllable equipment monitoring system. On the other hand, Advantech used the feedback from the company to add useful features to WISE-PaaS. This included an increase in the screen refresh rate for WISE-PaaS/SaaS Composer a cloud configuration tool with 3D & visible workflow, from seconds to milliseconds. Advantech also added support for RESTful APIs to facilitate the delivery of alerts to the internal mail system and changed the original queuing training to concurrent training by using the multi-task method to improve the training efficiency of a large number of models.

Through the AI equipment monitoring cloud platform, data was collected for the WISE-STACK private cloud platform, cloud devices were managed and configured, AI models were developed, and deployment and reasoning could be performed. For subsequent device operation and maintenance, equipment maintenance personnel can immediately monitor the status of the equipment to reduce production line downtime due to equipment failure, improve the service life of the equipment, and promote the function of automated remote diagnosis and preventive maintenance.

System Architecture

Project Implementation

Cloud

WISE-PaaS/EnSaaS: Industrial IoT PaaS Cloud Service

WISE-PaaS/APM: Asset Performance Management

WISE-PaaS/AFS: AI Framework Service

IoTSuite/Dashboard: Data Analysis and Visualization

WISE-PaaS/OTA: Over-the-air Centralized Remote Software Upgrade

Edge

WebAccess/SCADA: 100% Web-based SCADA Software

EdgeSync 360/DeviceOn: IoT Device Management

WISE-STACK-300: Fully Integrated Edge Intelligence Private Cloud

Smart Machine Box (SMB): Integrate Intel® 6th Generation Core™ i Processor Compact Fanless System MIC-7500 with 8-Ch high-accuracy data acquisition PCI Express Card PCIE-1802

Edge-to-Cloud AIoT Architecture to Enable Real AIoT-Powered Cloud Business Models

IoT Software Online Business Channel to Buy, Deploy, and Customize Industrial Software Needs

/MIC-7500_3D _B20181016110844.jpg)

-25/PCIE-1802_02----20220504105842.jpg)