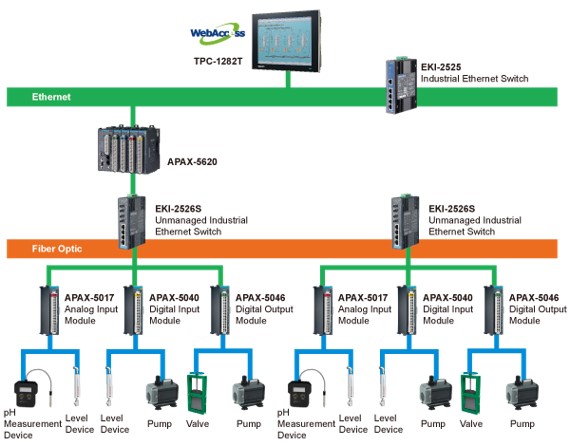

Remote and Centralized Monitoring System for Waste Water Treatment

15/08/2012

System Requirements

Project Implementation

| TPC-1270H | 12.1" SVGA LED LCD Celeron® M/ Touch Panel Computer |

| Advantech WebAccess | HMI/SCADA Software |

| APAX-5520KW | PAC Controller with Process & Logic Control Function |

| APAX-5017 | 12-ch Analog Input Module |

| APAX-5040 | 24-ch Digital Input Module |

| APAX-5046 | 24-ch Digital Output Module |

| EKI-2525 | 5-port Unmanaged Industrial Ethernet Switch |

| EKI-2526S | 4+2 100FX Port Single Mode Unmanaged Industrial Ethernet Switch |

System Description

At this data collection stage, fiber-optic communication plays a critical role in enabling the plant to expand its industrial network quickly and cost-effectively because EKI products support high-speed and long-distance transmissions. Meanwhile, with a high performance processor and large storage capability, the APAX-5520KW can act as a standalone controller for controlling I/O modules so as to provide local control features.

For remote management, Advantech provided a TPC-1270 12.1" SVGA LED LCD Celeron M/ Touch Panel Computer, with HMI/SCADA Software and Advantech WebAccess, to display all kinds of data immediately, therefore allowing engineers to remotely tune or manipulate the on-site equipment operations in the control center. The system also provides real-time alarms, historical data analysis, data sharing, automatic report generation, and many other management functions to meet the plant’s monitoring requirements as well as reaching the goal of centralized management and distributed control.

System Diagram

/EKI-2526S_S20100901143733.jpg)

/EKI-2525_02_S20160518163803.png)