Advantech LTE Routers: Helping Deliver an Efficient, Dynamic Application of Oilfield Fluids

5/06/2021

Fact I: The oil industry remains essential to the global economy

Oil remains one of the absolutely essential commodities in the world today. According to the Energy Information Administration (EIA), the United States is the number one oil-producing country. With production levels of 17,886,000 bpd (barrels per day) in 2018, there are approximately 11,000 oilfield workers in the industry at any given time. With increasing energy demand, especially among emerging economies like China, India, Latin America, and Africa, nations are looking for new oil and gas discoveries while using innovative approaches to reducing their environmental impact and attempting to become energy self-sufficient.

Fact II: The majority of severe oilfield accidents come from equipment failure

However, the U.S. Bureau of Labor Statistics estimates there are about 120 fatalities related to the oil and gas industry per year—with thousands more suffering injuries. Severe oilfield accidents involve the hazardous spilling of chemicals, fires, explosions, blowouts, fluid leaks, and more. Nevertheless, based on Sutliff & Stout, an injury and accident law firm, the most common types of accidents are related to oilfield injuries and accidents caused by equipment failure. Managing equipment on-site and in real-time has become a serious issue for companies trying to ensure worker safety and production efficiency.

The Problem: Unchecked oilfield production sites and “one-size-fit-all” chemical application methods

Oilfield production sites, with their uniform tanks and neat rows of piping, can appear deceptively simple. However, within and beneath these systems there is an incredibly dynamic chemical environment which, if unchecked, will quickly lead to premature equipment wear, lost productivity, and, potentially, the release of lethal poisonous gas. Oilfield’s processing chemicals presents another serious issue to be addressed. For decades, fixed-rate or “one size fits all” chemical application methods have been used to address oilfield fluids with fluctuating chemistries. This approach leads to inefficient chemical dosing and asset management schemes which negatively impact well production and equipment longevity.

Ensuring that chemicals consumed in the exploration, drilling, and production of oil are meeting engineering challenges—while at the same time optimizing production and maintaining safety—presents a major challenge that oilfield companies need to tackle urgently.

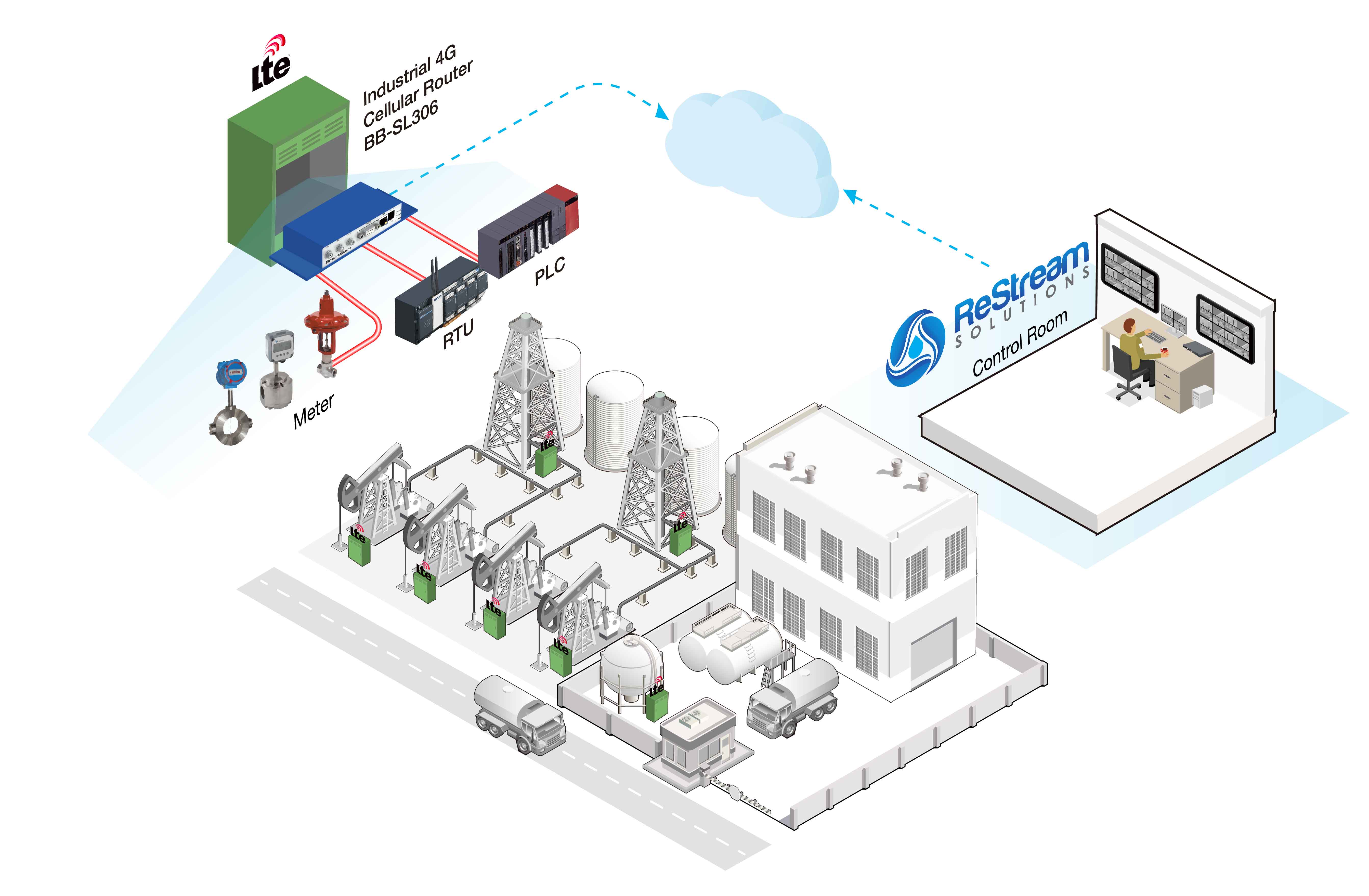

Advantech and ReSream demonstrate how wireless technology changes the oilfield industry by connecting fields to the cloud

ReStream, the leading company in the production of fluid monitoring and chemical application, cooperated with Advantech on LTE routers linking remote ProStream systems with cloud applications to make sure that the upstream, midstream, and downstream stages of chemical fluids in the oil fields were all monitored and functioning with the utmost safety and efficiency. By providing reliable on-site monitoring and precise chemical dosing, the chance of equipment failure was reduced while worker safety and production efficiency were strengthened.

The ProStream Production Monitoring Platform automates site-tailored chemical application processes

By integrating on-site monitoring, data collection, and cloud-based analytics within a robust hardware package, ReStream’s ProStream Production Monitoring Platform automated the chemical application process based on what happened at each site.

Advantech cellular routers connected the remote ProStream system to cloud applications

On-site monitoring and precision chemical dosing relies on a rock-solid network connection; which was why ReStream worked with Advantech’s SmartStart LTE routers for the linkage between remote ProStream systems and cloud applications. SmartStart’s on-board Wi-Fi radio provided a local connection for on-site technicians, and, in some cases, an access point for monitoring equipment spread throughout a well site. With a reliable LTE connection from the SmartStart LTE router, ReStream delivered on its commitment to gather more data, identify more problems, and offer more solutions. By providing reliable on-site monitoring and precise chemical dosing, the probability of equipment failure was lowered.

Advantech routing technology allows users to easily establish connectivity between isolated networks, giving greater flexibility for building secure applications. The involved technologies include VPNs, which provide secure remote access for users; network address translation (NAT), which hides users’ web servers behind our router with destination NAT; network-based firewalls, which secure infrastructure.

On-site monitoring and precise chemical dosing greatly enhance safety and productivity

The ProStream Production Monitoring Platform, along with reliable Advantech SmartStart LTE routers, provides an innovative approach to production monitoring, management, and chemical treatment applications. Flow assurance is achieved, asset integrity is ensured, production optimization improves, and digital monitoring comes equipped. Oilfield workers labor in safer conditions while companies enjoy maximized system efficiency and profitability.

Combining oilfield fluid monitoring with LTE technology creates smarter oil fields. A more efficient, dynamic application of oilfield fluids starts with Advantech LTE routers. Together with Advantech, energy producers are successfully riding the Industry 4.0 wave.

- For more product inquiry, please contact iiot.tech@advantech.com

- Advantech experts will be providing you with dedicated support soon!

-25/ICR-2431_820x82020210427192344.png)

/LR77v2B_PLAST_DA00000_500px20180625150049.jpg)

/BB-AP-AGNSS-SMA_500px20180625151506.jpg)