Tier-1 EV Thermal Manufacturer Significantly Elevates Overall Visibility in Machine OEE and Facility Energy through Unified IIoT Platform

1/26/2024

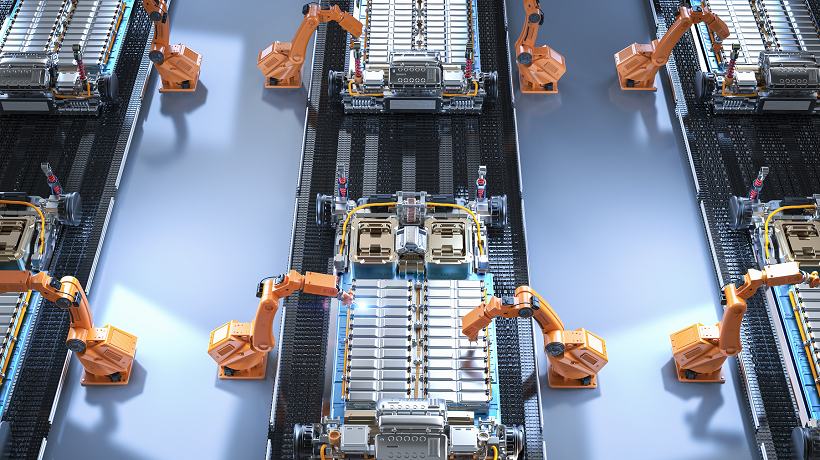

Industry: EV Thermal Manufacturing

Introduction

Since 2008, Amulaire Thermal Tech has focused on developing high-power electronic thermal components, supplying major Tier 1 automotive manufacturers. Evolving into a Tier 1 supplier, it now holds a leading market share in automotive thermal module solutions. In contrast to the high-tech industry, the traditional automotive manufacturing sector generally lags behind in terms of digitalization and machine intelligence. Actively pursuing digital transformation, Amulaire Thermal Tech responds to rising energy costs and Tier 1 automakers' requests for future low-carbon emission suppliers in the supply chain. Consequently, the company faces significant pressure to digitally address both machine and energy consumption processes with a reduced environmental impact.

Aim to Create an Open Centralized IIoT Architecture

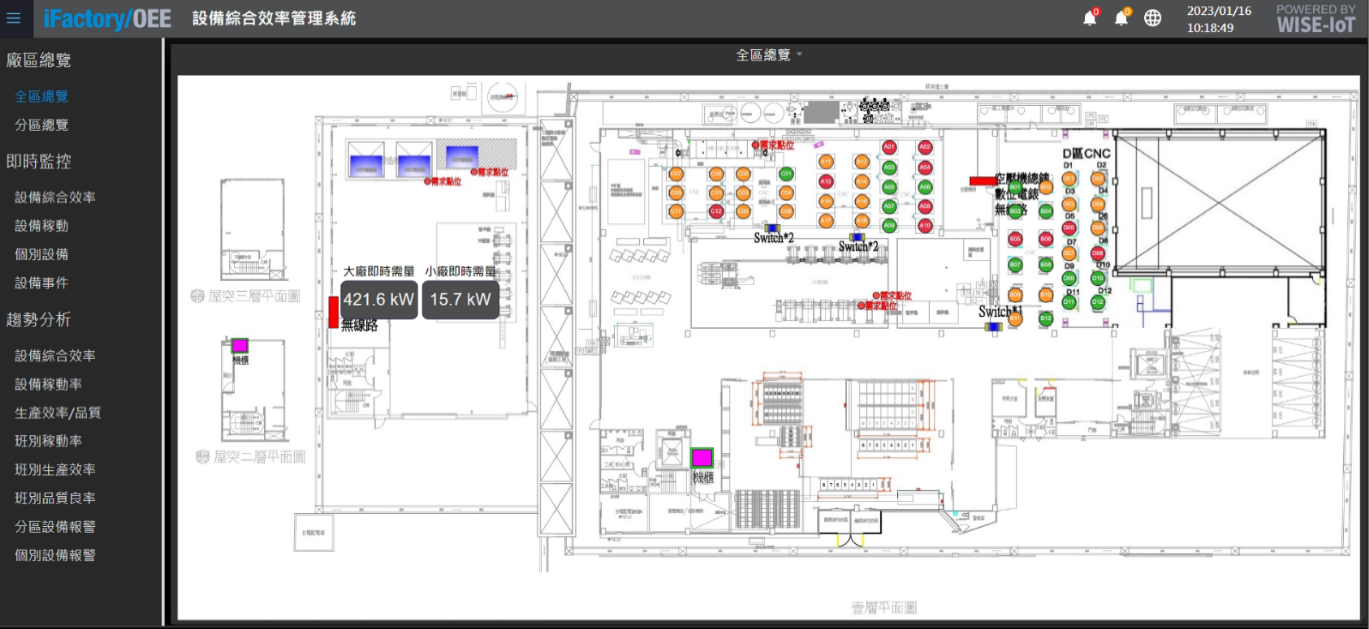

Amulaire Thermal Tech aims to create an open yet centralized IIoT architecture. This design allows data to seamlessly connect with the existing system (IT) and also enables flexible communication with shop floor machines (OT) that were previously unable to communicate.

- The team utilized Advantech Gateway Edgelink to establish machine connectivity across its CNC fleet and facilities, aiming to visualize OEE and energy data. Surprisingly, the production visualization, typically a process taking six months or more, was successfully launched in just two weeks.

- Just-in-time manufacturing is crucial for shop floor managers to gain project visibility. An engineer-friendly OEE/Energy dashboard template, easy to customize, is also essential to encompass their daily activities.

- Ensured buy-in from all organizational levels, especially the operations system group. Aligned Key Performance Indicators (KPIs) with the entire team to facilitate leveraging the newly collected data.

- Integrating SAP ERP with the IIoT platform was a pivotal request.

" Amulaire Thermal Tech now has two plants in Taiwan, and in the near future we will for sure expand to overseas. We need a system that can integrate IT data and OT production together, streaming to a centralized location to gain overall visibility across multiple plants. This is what we are looking for from our digital transformation partner." - Mr. Kao, Director of Amulaire Thermal Tech.

Application Solutions

iFactory Application Modules

iFactory solutions are designed for plug-in visualization and data analysis on the manufacturing shop floor. It enables manufacturers to quickly visualize values from IIoT implementation and easily scale from machine to machine and site to site through modular solutions. This project includes the following:

Machine Performance Module (OEE)

- Equipment utilization rate / output rate / quality rate tracking.

- Single machine parameter recording / downtime error codes logging.

Energy Monitoring Module (FMS)

- Energy baseline / significant energy consumption tracking.

- Multi-dimensional energy comparison tool for better energy reduction actions.

Digital Equipment Maintenance Module (Maintenace)

- Auto-maintenance ticketing system (usage-base maintenance).

- Digital calendar and management console (time-base maintenance).

- Paperless digital checklist and tracking dashboard.

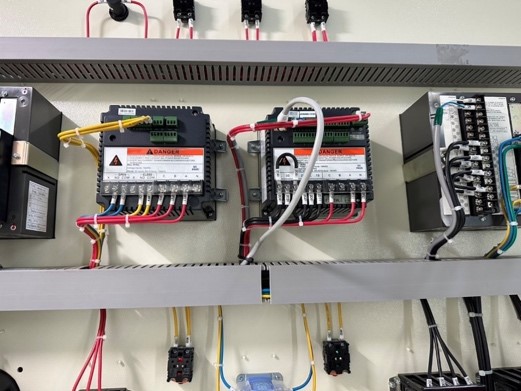

EdgeLink, an IoT gateway software, connects 200+ edge devices and platforms. Advantech Edgelink gateways gather data from machines with available fieldbus ports, utilizing a local rules engine. The gateways publish the relevant data to the iFactory platform using MQTT.

On-Site ECU Gateways

ECU Gateways Connect With Smart Meters

- Configure a gateway using Windows utility.

- Supports multiple southbound and northbound communication protocols, including MQTT, AMQP, LwM2M, OPC UA, Modbus, IEC-104, and DNP3.0.

- ‘One-click’ downloads for data communication and network configurations.

- Unified device networking management

- Real-time gateway status monitoring

Conclusion

Following the iFactory system implementation, Amulaire Thermal Tech's digital capabilities and resilience have steadily improved. Digital modules now provide managers and operators with clear visibility into production and energy.

" We have elevated the expertise of operators now by gaining more insights. For example, now operators will be able to quickly analyze production issues and improve bottlenecks better, because they are not preoccupied by paperwork and time consuming communication. With data visibility, they are free from unnecessary repetition and have more time to improve efficiency based on dashboard information. Quality rates and production efficiency are projected to go up by 5% and 15% respectively. Additionally, by applying energy monitoring systems, we progressively achieved energy-saving and carbon reduction effects of 5% in 2023. In the long term, this gives better assurance to our customers that Amulaire Thermal Tech is a Tier1 supplier with intelligent manufacturing capabilities. " - Production site manager, Amulaire Thermal Tech.

Quality Rate

↑ 5%

Production Efficiency

↑ 15%

Energy-saving and Carbon Reduction

↓ 5 %

Why Advantech

- Advantech delivers a comprehensive edge-to-cloud, end-to-end solution, significantly reducing customers' integration effort and time in digital visibility projects.

- Advantech's intelligent gateway offers engineers one-click data access convenience, supporting over 200 device protocols.

- iFactory applications, such as OEE/FMS/Maintenance, offer users an intuitive dashboard template and a ready-to-use data mapping schema. This allows users to quickly plug in data and gain insights in a short time.

/ECU-1152_03_B20160517142423.png)

-25/Project_02--_Vertical20220406173334.jpg)