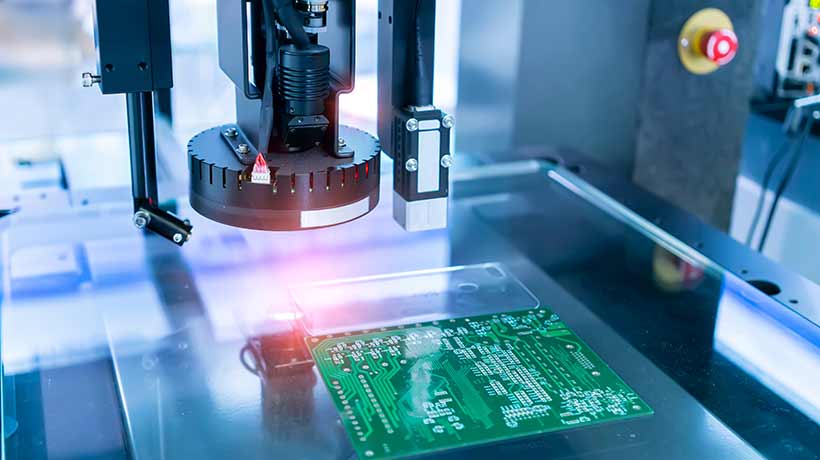

Enhancing PCB Quality with an AI Defect System

28-12-2023

Traditional PCB manufacturers usually use rule-based machine vision algorithms for defect inspection and need a highly skilled inspector to recheck. Our customer, a well-known PCB manufacturer with three major manufacturing centers in Taiwan, China, and Japan was planning to improve its dual in-line package (DIP) and SMT production line’s yield rate by utilizing AI technology. Currently, each PCB still needs manual rechecking after automated visual inspection. This is because, commonly, about 2-3 electrical components on a PCB are not accurately recognized from data captured from 3D cameras due to low contrast. As a result, the underkill rate of AOI screening reaches up to 70-80%.

Challenge

To enhance yield rates, the customer decided to adopt deep learning CNN to replace the existing rule-based AOI approach. On average, it takes 7.3 months to transition an AI initiative from prototype to production. An end-to-end AI-based defect inspection solution includes reliable, powerful AI systems and high-precision, multidefect-inspection software with AI algorithms. Furthermore, since the customer was looking for continuous accuracy improvement, AI model retraining at the production line is required.

Solutions

Advantech has partnered with Phison to take on these challenges. Phison's aiDAPTIV+ AOI service run perfectly on Advantech’s AIR-030 Jetson Orin AI system for inferencing, along with the powerful AIR-520 4U AI workstation, which is NVIDIA Certified with 2x RTX A5000. for retraining at the edge. The Advantech AIR-030, powered by the NVIDIA AGX Orin, provides high compute power to execute vision and inference tasks including image enhancement, defect identification, and detection in real time. The compact AI system features rich I/O connections including CANBUS and COM for motion control and sensors, PoE expansion for CCD cameras, and LAN for data transmission. The captured 3D images are not only sent to AIR-030 for inferencing but AIR-520 is also installed on the production line for AI model retraining.

Complicated real-time AI training and high-performance computing were performed on AIR-520 locally with its AMD

EPYC 7000 Zen3 processor and two NVIDIA RTX GPU cards. The Advantech AIR-520 supports up to 45 TB of

storage so that all image data used for AI model training can be stored locally to ensure classified data is secure. It

also offers 2 x 10GbE and 2 x 2.5GbE for massive data transmission. Lastly, it has a built-in 1200W power supply ,

which makes it easy for equipment integration.

The precise AI model running on both AIR-030 and

AIR-520 was developed by Phison's aiDAPTIV+

AOI service. In the early stages of research and

development, Phison assisted in collecting AOI data

from the production line and utilized a generative

adversarial network (GAN) framework to approach

generative AI, generating additional defect images

for training. This approach enabled Phison to build

a foundational model with significant performance.

Phison's aiDAPTIV+ AOI service also provided

customized fine-tuned models tailored to specific

production lines, accommodating different situations.

Compared to other AOI AI solutions that use general

models, customized models better meet customer

requirements.

With the AI model in operation, data is selectively

used to retrain the model through MLOps, optimizing

its performance over time. This process significantly

enhances the model's accuracy in identifying product

defects. After implementing Phison's aiDAPTIV+

AOI service, the first pass yield (FPY) increased

from 74% to 99%, reducing the workload of reinspection

operators by 96%. The escape rate

could be decreased to lower than 100 ppm, thereby

significantly reducing the risk of missed defects.

Benefits

• Powerful edge inference system with vertical I/O tailored to the application.

• Edge AI workstation with BMC server-grade

manageability and dual GPU cards for training.

• Accelerated application deployment with an ISV

partner.

Results

• Decreased the underkill rate by 99%

• Reduced the manual

reinspection workload of by 92%

• Enhanced the yield rate by 95%

-25/AIR-520_04--20240503141558.jpg)

-25/AIR-030_04--20230601175550.jpg)