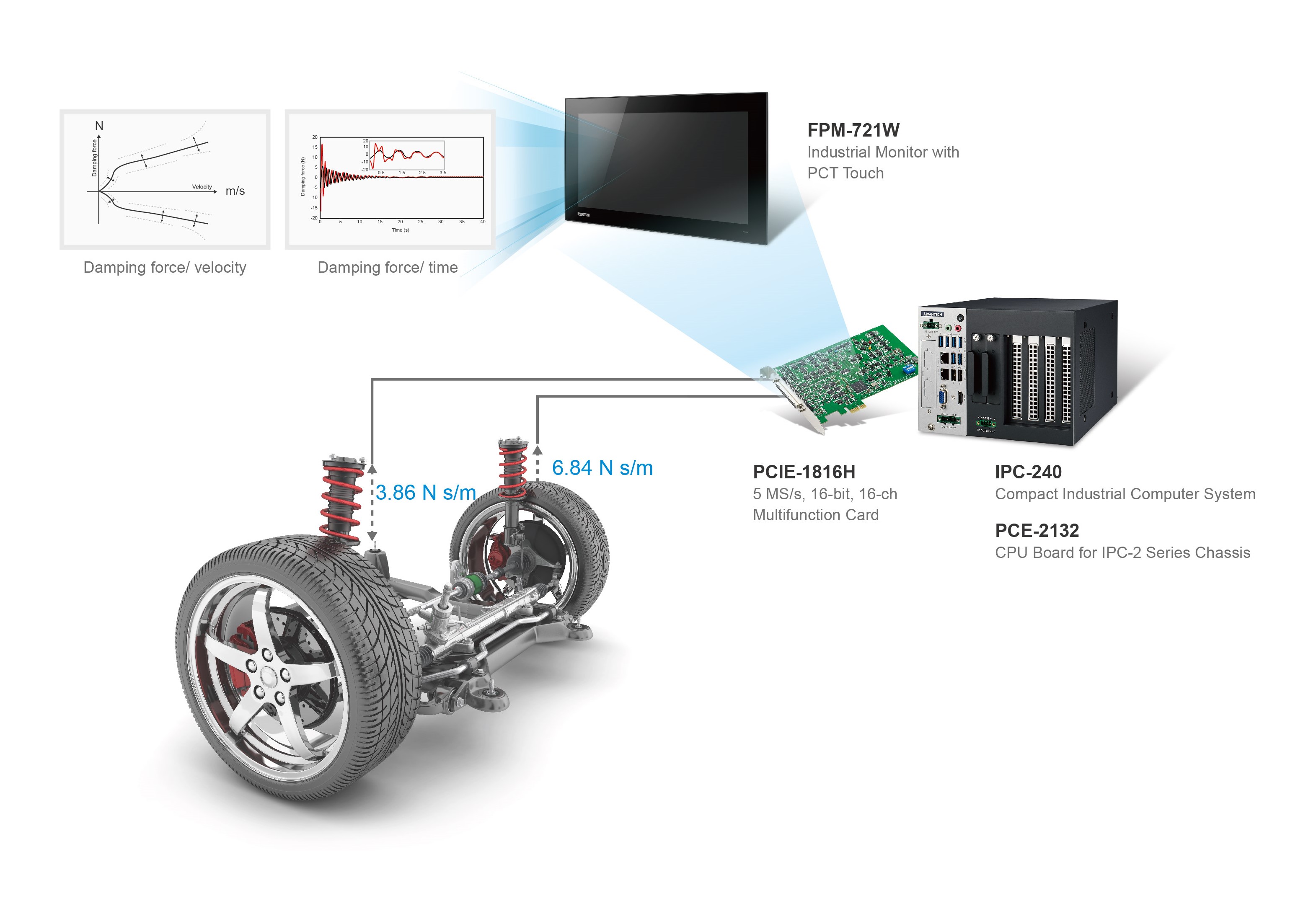

Vehicle Shock Absorber Automatic Test System

08-10-2024

Project Introduction

The shock absorber suspension system is a critical component of a car, and its performance directly affects the car’s handling safety and comfort. Shock absorber malfunctions can affect an automobile’s stability and also have a direct and critical impact on the active safety of the vehicle. Therefore, the operational status of the absorber is absolutely essential to driving safety. This system can test the damping features and power characteristics of shock absorbers, reducing shock absorber test cycles and improving efficiency.

System Requirements

- The sine and cosine noise wave generators have been designed to test the damping, speed, and displacement characteristics of the automobile shock absorbers

- It uses simulated signal fitting, differentiation, and filtering processes to observe the dynamometer and speed curves.

- Damping force signals are monitored and spectrum analysis is performed in order to determine whether the shock absorber passes the test.

- Data storage and replay functions.

Project Implementation

- IPC-240: Compact Industrial Computer Chassis for PCE-2000 Series CPU Board

- PCE-2132: LGA1200 10th Generation Intel® Core™ i9/i7/i5/i3 & Pentium®/Celeron® CPU Board for IPC-2 Series Chassis

- PCIE-1816H: 5 MS/s, 16-bit, 16-ch Multifunction PCIE Card

System Description

- The 1M/S sampling rate and 16-bit resolution of the PCIE-1816H data acquisition card can accurately collect the damping force changes captured by the pull/pressure force of the sensors. In addition, the absorber’s displacement variations can be changed into voltage signals through the differential transformer displacement sensors, and finally collected. - IPC-240 is a Compact-size box PC; its anti-vibration capacity can fully adapt to the rocking motions produced by the shock-absorber testing machine’s operations. The desktop-level processing also delivers high sampling rates for high-res applications.

- IPC-240 is a Compact-size box PC; its anti-vibration capacity can fully adapt to the rocking motions produced by the shock-absorber testing machine’s operations. The desktop-level processing also delivers high sampling rates for high-res applications.

System Diagram

Conclusion

The shock absorber suspension system is crucial for a car’s handling, safety, and comfort. Malfunctions can severely impact vehicle stability and safety. Efficient testing of shock absorbers is vital, and Advantech's technology enhances this process. The PCIE-1816H data acquisition card, with a 1M/S sampling rate and 16-bit resolution, precisely captures damping force changes, while differential transformer displacement sensors convert displacement variations into voltage signals. The IPC-240 box PC, with its robust anti-vibration capacity and high processing power, ensures accurate and efficient testing, thereby improving the reliability and performance of shock absorbers.

-25/IPC-240_02_Square--20210826152858.jpg)