Data Acquisition Solution with a High Price-Performance Ratio for Distributed Temperature Sensor Systems

8/17/2018

Introduction

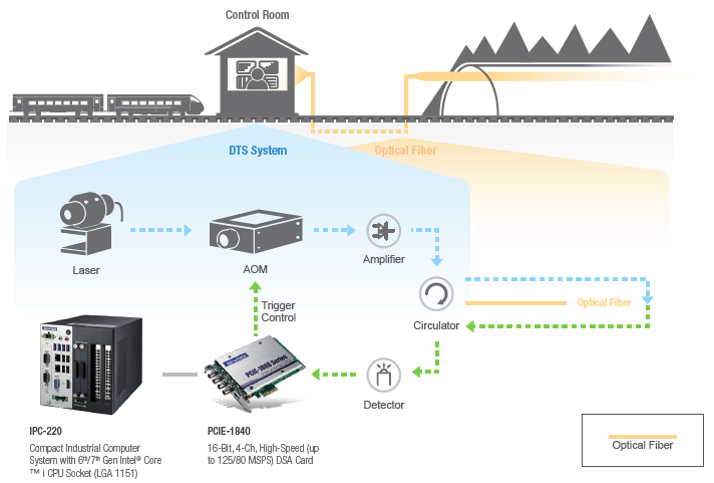

Rather than using temperature sensors to monitor temperature,distributed temperature sensor (DTS) monitoring systems use optical fibers as temperature sensing devices. With temperature sensing optical fiber cables installed in the monitored area and connected to a host computer, measurement software can be used to display real-time temperature changes. Benefiting from the advantages of optical fibers, which include being unaffected by electromagnetic interference, freely bendable, small and easy to install, and able to support detection in large areas without blind spots, DTS systems are especially suitable for high-risk, disaster prevention applications, such as power cables, oil/gas pipelines and storage tanks, and highway/railway tunnels.The quality of DTS systems is determined by the system’s ability to quickly and accurately continuously monitor the temperature of all sites along the cable. For system integrators, the optimal data acquisition (DAQ) product must be selected during development to ensure that the system performance meets market requirements and exceeds that of their competitors.

System Requirements

However, the new hardware needed to offer a high performance.price-performance ratio. Specifically, the digitizer needed to support a sampling rate of no less than 100 MSPS, 16-bit resolution,simultaneous analog sampling, data transfers through direct memory access (DMA) for faster processing, and large on board memory to ensure efficiency.

Regarding the computer, the client required a system equipped with a high-performance processor, multiple PCIe slots, and a storage device with fast read/write speeds, as well as suitable protection to withstand industrial usage.

System Description

By perfectly integrating the two products, the DAQ system is capable of triggering acousto-optic modulators (AOMs) that control lasers to send a laser pulse of set width to the propagator and then to the optical fiber cable, while also receiving the backscattered signal of the laser pulse source from the photo transducer. After processing on the host computer, the signal shows the temperature distribution for the entire temperature sensing cable. The PCIE-1840 digitizer is the most important component of the solution because it is this hardware that simultaneously triggers transmissions of the laser pulse while receiving the backscattered signal. This digitizer,with its sampling rate of up to 125 MSPS, 16-bit resolution, and four simultaneous analog input channels, enables precise and speedy data collection. Moreover, the inclusion of 2 GB of onboard memory satisfies the requirements for high-speed data transmissions. Data transmissions through CPU-independent DMA accelerate the overall transmission rate and reduce CPU load.

To further accelerate DMA data transmissions, Advantech adjusted the driver for this project by enhancing the transmission rate more than tenfold. In addition, because the strength of the laser beam is determined by the width of the laser pulse, Advantech customized the PCIE-1840 board with a field-programmable gate array (FPGA) to assist users with setting the pulse width.

Conclusion

The performance of the client’s DTS system increased with the inclusion of the AiMC-3201 high-performance microcomputer. Advantech also customized the PCIE-1840 board according to their specific needs to significantly improve the overall system efficiency.

Finally, because of the positive results of introducing Advantech’s DAQ solution, the client company has decided to copy this solution with other systems.