Advantech Builds AI Safety Solution for Its Factory with NVIDIA Jetson Platform Services and Generative AI

6/3/2024

Advantech, a leading provider of AI platforms, has collaborated with NVIDIA to utilize generative AI at the edge with the new NVIDIA Jetson Platform Services to quickly create an AI safeguard solution for the industrial PC board wave soldering machine in the Advantech factory. The project took only three weeks from development to implementation, accelerated by the NVIDIA Jetson Platform Service’s API-driven capabilities for building generative AI. This successful start opens up even more future opportunities to leverage generative AI in the Advantech factory.

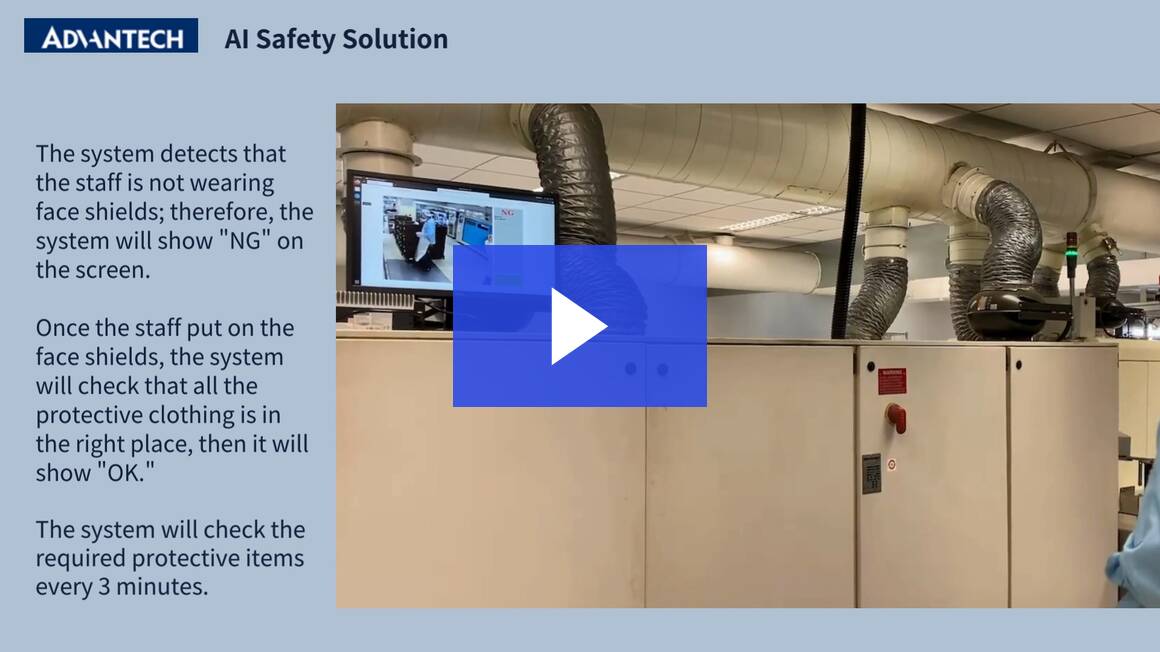

Advantech manufactures thousands of industrial PC boards per day. Each of them needs to pass through a wave soldering machine to fix the components on the board. The wave soldering machine incorporates a solder reservoir that is precisely controlled and maintained at temperatures ranging from 180 to 450 °C, depending on the solder type and machine model. High heat is emitted when opening the wave soldering machine. To ensure working safety, Advantech previously used a paper checklist to verify that staff were wearing protective clothing such as aluminized heat protection aprons, gloves, masks, face shields, and steel-toed shoes. However, manual inspection is error-prone, putting Advantech factory staff at greater risk of injury. Therefore, Advantech decided to use AI as a safeguard to check for compliant protective clothing every time the wave soldering machine is opened.

→ Before opening the wave soldering machine, the responsible staff need to wear protective clothing such as aluminized heat protection aprons, gloves, masks, face shields, and steel-toed shoes to prevent exposure to high heat ranging from 180 to 450°C.

3 Weeks to Make AI Working in the Factory

The full AI deployment process took only 3 weeks. Advantech set up cameras on the wave soldering machine that connect to the industrial edge AI system MIC-733-AO, based on NVIDIA Jetson AGX Orin. The MIC-733-AO is integrated with NVIDIA Jetson Platform Services. Once the AI system verifies that the staff is wearing protective clothing, it sends the approved signal to the wave soldering machine.

A new feature of the NVIDIA JetPack 6 software development kit, the Jetson Platform Services provides pre-built and cloud-native software services to fast-track the development and deployment of sophisticated edge AI applications. By leveraging the NVIDIA Jetson Platform Services, Advantech only needed to do prompt engineering and make simple adjustments to identify aluminized heat protection aprons, gloves, masks, face shields, and steel-toed shoes, thus skipping the lengthy AI development process of building YOLO models, data collection, data labeling, training, and retraining. The AI deployment time was greatly reduced from 6 months or a year to just 3 weeks, and without sacrificing the solution’s accuracy.

The Advantech AI safety solution is simple, cost-effective, and time-efficient. The NVIDIA Jetson Platform Services helped significantly lower Advantech’s barrier to deploying safety AI, as shown through this successful project with the wave soldering machine. Advantech plans to continue to collaborating with NVIDIA to implement more AI-automated solutions in the factory, including fire security check etc…. To know more information about AI Safety Solution in Advantech factory, you are welcome to contact Advantech, or register Advantech Computex AI Meetup and NVIDIA at Computex .

-25/MIC-733_03-----(1)20221028164426.jpg)