Success Stories: Edge AI in Factory Automation and Robotics

01-12-2023

The global artificial intelligence in manufacturing market is expected to reach USD 16.3 billion by 2027 according to MarketsandMarkets. AI has revolutionized industrial fields by making it much more efficient, productive and cost-effective. Advantech provides hardware and software integrated offerings to help customers accelerate their AI-powered defect inspection, robot, and workplace safety applications

Case 1-Leveraging GenAI and LLMs for Enhanced Decision Support in Manufacturing

Electronics manufacturing involves complex material management and production processes, requiring multiple information systems and a large number of human resources. Incorporating LLM AI into a decision support system can lead to enhanced efficiency, improved product quality, better customer satisfaction, and more strategic decision-making. It helps in various ways such as data analysis & insights, process optimization, customer support and employee training, ultimately contributing to the overall success and competitiveness of the electronics manufacturer.

Solution:

• AIR-520 Edge AI Server System with NVIDIA RTX 6000 Ada GPU Cards

• aiDAPTIV+ ai100 AI SSD

• NVIDIA AI Enterprise

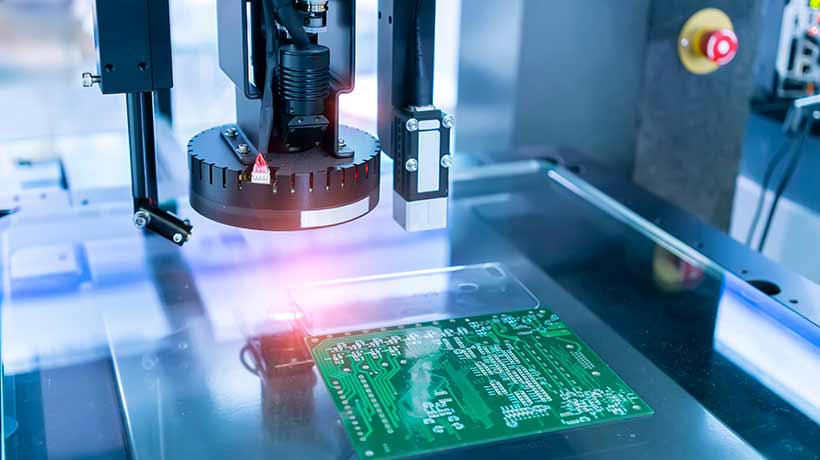

Case 2-PCB defect inspection

Traditional PCB manufacturers usually use rule-based machine vision algorithms for defect inspection and need a highly skilled inspector to recheck. Our customer, a well-known PCB manufacturer with three major manufacturing centers in Asia was planning to improve its dual in-line package (DIP) and SMT production line’s yield rate by utilizing AI technology. Currently, each PCB still needs manual rechecking after automated visual inspection. This is because, commonly, about 2-3 electrical components on a PCB are not accurately recognized from data captured from 3D cameras due to low contrast. As a result, the underkill rate of AOI screening reaches up to 70-80%.

Challenge:

• Long development time from prototype to production.

• Continuous accuracy improvement is required

Solutions:

Inference- AIR-030, Retraining- AIR-520

Software- Phison’s aiDAPTIV+ AOI Service

Case 3-Power plant inspection robot

Our customer stands as a prominent company in China,

spearheading the development and implementation of intelligent

inspection solutions for electrical equipment. Committed to aiding

power plants and electrical substations, their mission is to address

challenges such as diminishing manual inspection requirements,

lowering maintenance costs, and mitigating the risk of safety

incidents through AI technology and video analysis. By integrating

cutting-edge technologies like drones, cameras, and autonomous

robots, they have effectively and extensively incorporated AI

solutions into diverse facets of power equipment operations such

as transmission line maintenance, defect inspection, security

monitoring, and distribution maintenance.

Challenge:

• AI computing power dedicated to processing images and translating diverse values from electricity meters

• Harsh outdoor environments

• Developing different software around Ubuntu

Solutions:

Inference- AIR-030, OS- Ubuntu, SDK- JetPack 5.0 and above

Case 4-Workplace safety

Workplace safety is vital to protect employees from hazards and other dangers that may occur in the workplace. The Liberty Mutual Workplace Safety Index reported that for every $1 a company invests in workplace safety, the result amounts to a $4 return on investment. Our customer was looking for a vision AI solution that can help the manufacturing manager ensure operational safety while also improving efficiency and productivity with two specific objectives:

• To check if an operator is wearing personal protective equipment (PPE) including cap, antistatic clothes/wrist strap, and mask properly

• Detection of idle time to raise assembly line productivity

Challenge:

• High level of detection accuracy under poor lighting and image quality caused by environmental conditions

• Real-time notification for manufacturing managers

Solutions:

Inference- AIR-020, Software- CyberLink FaceMe, SDK- NVIDIA JetPack SDK

Case 5-Enhance Manufacturing Efficiency with AI-based Transfer Robots

The modern electronics manufacturing industry faces significant intralogistics challenges, such as high-frequency material replenishment, long-distance material transfers, growing labor safety concerns, and increasingly complex working environments. By implementing an AI-powered Autonomous Mobile Robot (AMR) system, manufacturers can address these issues effectively.

Challenge:

• Ensuring stability and flexibility while minimizing vibrations

• Optimizing route planning and improving obstacle avoidance accuracy

• Maintaining a high standard of safety for human-robot interactions

• Fine-tuning cobot design to accommodate specific infrastructure needs

• Autonomously transporting materials over long distances and at high frequencies

• Performing various tasks, such as real-time image processing, analysis, local inference, and material delivery Incorporating lightweight, long-lasting battery solutions for 24-hour autonomous cyclic operation and efficient charging

Solutions:

Inference- AIR-030, OS & SDK- Pre-loaded Ubuntu image and JetPack SDK

-25/AIR-030_04--20230601175550.jpg)

-25/AIR-500D_02--20220422155331.jpg)

-25/AIR-150_03--20231110104228.jpg)

-25/AIR-510_04--20240806132906.jpg)