ESG Intelligent Management - LoRaWAN Facility Monitoring Enhances Hospital Operational Efficiency

21/05/2024

Location: Taiwan

Background

A hospital in Taiwan, one of the leading medical institutions, has always been committed to providing high quality healthcare services. However, with global sustainability issues coming to the forefront, the hospital recognized the need to re-evaluate its operations from an energy management and environmental sustainability perspective. As a result, the hospital has embarked on a series of initiatives to improve energy efficiency and minimize environmental impact in response to ESG issues.

First, the hospital focused on key units such as the inpatient building and the Proton Center to identify potential improvements through statistical analysis of energy demand. In addition, the hospital is focusing on improving the efficiency of equipment operations, especially the monitoring and maintenance of equipment such as chillers and gas systems, which are in continuous operation and whose proper functioning is critical to the hospital's energy consumption. By monitoring the operation and maintenance of key equipment in the hospital, we can ensure the efficient, stable and safe operation of the hospital's various operating systems, and realize the effective management of energy use and equipment maintenance.

System Requirements

Recognizing the importance of global ESG (Environmental, Social and Corporate Governance) issues, this hospital organization hopes to contribute to environmental protection through energy saving and carbon reduction. Secondly, manual inspections were previously used, but faced inefficiencies and a lack of manpower in the hospital, as well as problems such as limited scope of monitoring and the possibility of manual misjudgment. It is hoped that the introduction of the equipment monitoring program will improve these problems and enhance the overall efficiency to ensure uninterrupted operation of the hospital's environment and patient maintenance system as a 24-hour operating venue.

The system should address the following features:

- There is no need for major construction to avoid expensive costs and disruptions to patient recuperation. Secondly, the system needs to be able to effectively monitor and improve the efficiency of energy usage to reduce inspection and maintenance costs and minimize the risk of equipment downtime.

- Considering the vast area of the hospital building, the many obstacles such as walls and equipment, and the fact that most of the pipelines are located in electrical rooms or between ducts, making it difficult to transmit wireless signals, a long-distance, high-penetration communication solution is required to ensure stable data transmission. Since many devices in the hospital, such as medical carts, use Wi-Fi and Bluetooth signals to transmit data, and the traditional 2.4G band is prone to interference, the Sub-GHz band was chosen for wireless communication.

Project Implementation

- WISE-2410: LoRaWAN Smart Vibration Sensor

- WISE-2200-M: LoRaWAN 1RS-485 I/O Module

- WISE-4610: LoRaWAN IoT Wireless Modular I/O

- WISE-6610: Industrial LoRaWAN Gateway

- MIC-770 V3: High Performance Compact Fanless System

System Description

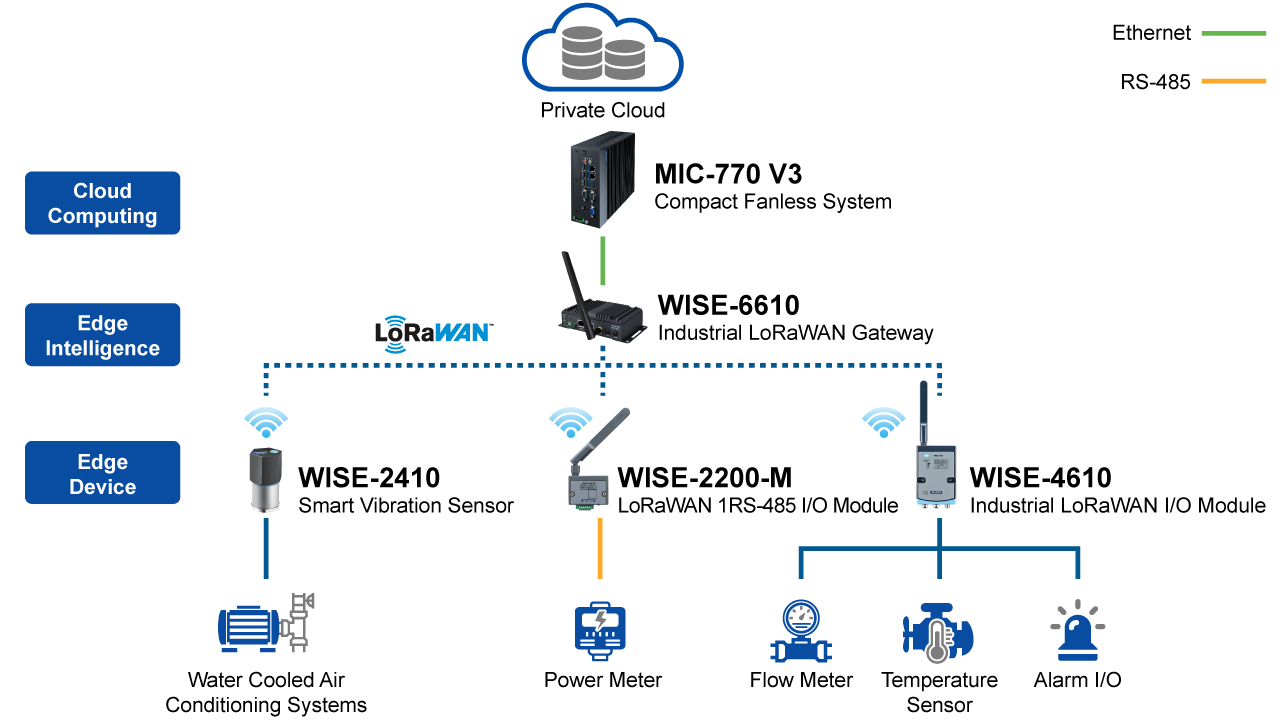

The hospital chose to adopt Advantech's LoRaWAN solutions, which utilizes LoRaWAN technology to connect information from edge sensors to the cloud. Compared with the limitations of Wi-Fi, such as short coverage distance and time-consuming wired network installation, LoRaWAN has the key advantages of long-distance connection, wide coverage, high penetration rate, and low power consumption, and does not require wiring and cables.

The WISE-2410 vibration sensor is held in place by a magnetic base on equipment such as chillers and gas systems in continuous operation. The sensor transmits rotational speed and acceleration characteristics to the WISE-6610 gateway via the LoRaWAN wireless network. Meanwhile, the WISE-2200-M LoRaWAN 1RS-485 I/O module receives data from the power meter, which is input via RS-485 signal. In addition, the WISE-4610 LoRaWAN IoT wireless I/O module is installed on the gas distribution system to receive and monitor data from the flow meter, thermometer, and alarm I/O devices, and both the WISE-2200-M and WISE-4610 transmit data via LoRaWAN to the WISE-6610 LoRaWAN industrial gateway. Data from the WISE-6610 is transmitted over Ethernet to the MIC-770 V3, a fanless system located in the hospital's administrative office. The computer visualizes and connects to the hospital's management system, and the collated data is uploaded to the hospital's in-house private cloud for further analysis by the relevant units.

- The WISE-2410 LoRaWAN vibration sensor for rotating facility inspection applications is compliant with ISO-10816. The WISE-2410 also supports 3-axis vibration detection and temperature sensors, and is IP66 rated, with a wide temperature range (-20 ~ 80°C) to overcome the harsh environments of a continuously operating chillers or gas system equipment.

- The WISE-2200-M is a plug-and-play LoRaWAN RS-485 I/O module that allows users to easily configure data acquisition settings and capture sensor and meter data via its supported Modbus/RTU protocol. Its wide temperature design (-25 ~ 70°C) allows the device to operate in extreme industrial environments.

- The WISE-4610 is equipped with the WISE-S617 modular I/O solution to meet the needs of different types of remote facility monitoring and control applications. It has DO for switching control and AI/DI/RS-485 channels for sensor and PLC connection.

- The WISE-6610 is a LoRaWAN gateway that supports the Modbus TCP protocol for connecting to SCADA systems in control rooms.

- The MIC-770 V3 compact fanless system is equipped with the latest 12th/ 13th Gen. Intel® Core™ processor, delivering exceptional computing capabilities for real-time data analysis. Its ruggedized design also ensures 24/7 continuous operation in demanding environments.

System Diagram

Conclusion

The LPWAN technology and plug-and-play product design ensure the stability and quick and easy deployment of the facility monitoring system. In addition, the WISE-2410 and WISE-4610 are battery-powered and support industrial control protocols, enabling high-performance operation in areas where power supply is not feasible, and supporting a wide range of application requirements, including RTU RS-485 and TCP support for SCADA systems. After the first phase of implementation in the customer's inpatient building, Advantech's facility monitoring solution significantly improved the customer's operational efficiency, and the customer has decided to continue to implement the solution in its organizations.

-25/WISE-461020240702102109.png)

/WISE-2410_04-_B20191226121551.jpg)

-25/WISE-2200-M_03--20220420151842.jpg)

-25/MIC-770-V2_03---(1)20221207100333.jpg)

-25/WISE-6610_02--20240202160416.png)