High-speed and High-precision Screen Printing Machine

23.08.2021

Introduction

The customer is a world-leading manufacturer of screen printers in Taiwan and is famous for manufacturing high-speed automatic cylinder screen printing equipment. The customer wanted a more reliable EtherCAT I/O system to replace their existing system.

The new solution had to work with Beckhoff’s XFC architecture. The customer finally chooses Advantech not only for the AMAX-5000 series timestamp and encoder modules which were able to meet the customer’s requirements, but also for our strong technical support.

Project Requirements

The customer’s screen printing machines need high precision control and high positioning accuracy to ensure excellent print quality output. The I/O system for the machine needed to work with 2 x fast squeegee blades, paper detection sensors, and encoder so that it can effectively improve the accuracy of the printing.

In addition, to ensure the productivity of the printing machine, the I/O system required a high-speed response time to keep up with other mechanical components.

Lastly, because it would take a lot of time to replace the entire control and I/O system, the customer decided to replace the original I/O system in the first phase. To meet the demand of the customer, Advantech needed to seamlessly integrate their AMAX-5000 I/O system into their original legacy control system.

Project Solution

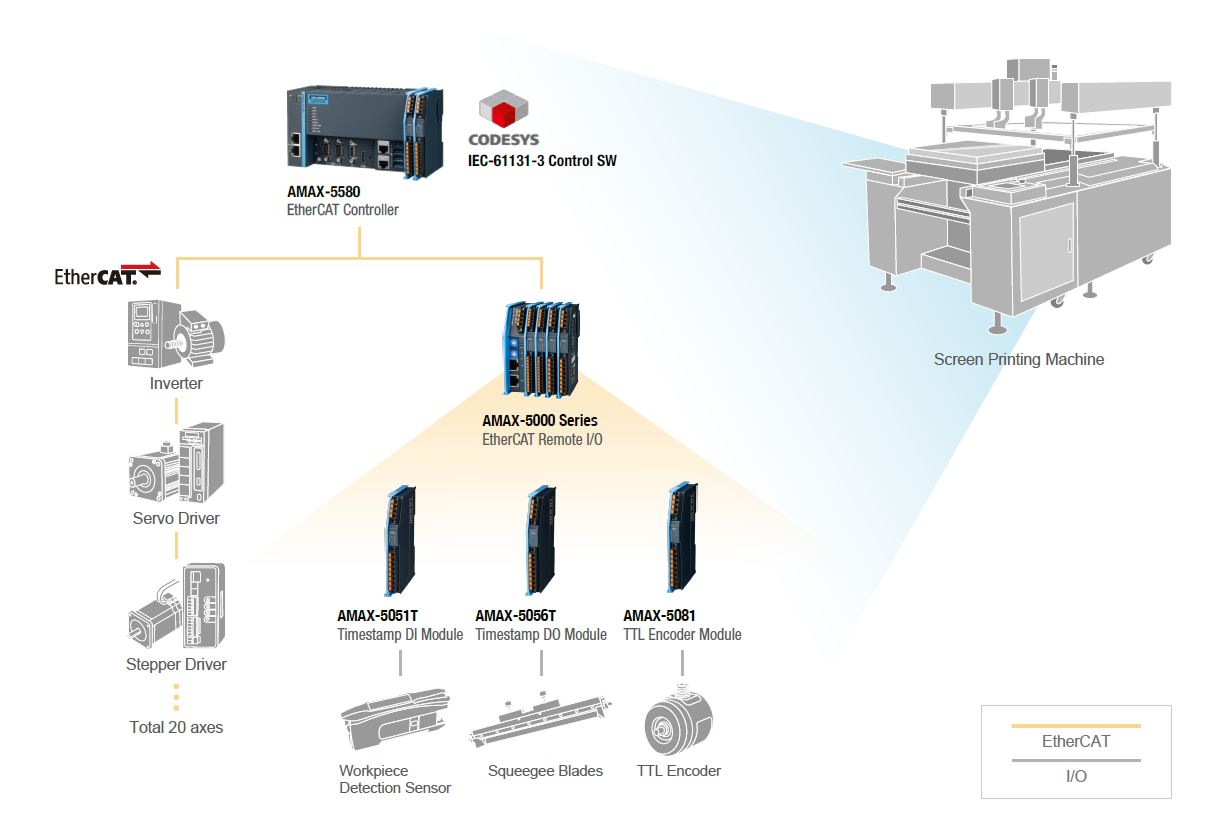

The control system is based on the distributed architecture of EtherCAT. Various motors and sensors are connected through EtherCAT, and accurate position information is acquired through EtherCAT I/O, which feeds back precise control output signals. To achieve printing precision, an Advantech AMAX-5051T timestamp DI module was incorporated to locate the precise incoming time of paper and convert it into position data with AMAX-5081’s encoder reader module. This would trigger a squeegee blade at the precise moment to start distributing the inks using AMAX-5056T’s timestamp DO module. The 1ns level precise time stamp module is fast and accurate enough for precision machine control and high quality printing. The 10MHz encoder reader also helps to speed up the response time of the process, enabling maximum machine production and ultimate efficiency.

Finally, the AMAX-5000 product series are all standard EtherCAT slave devices and with our professional technical support, the customer’s printing machines could be seamlessly integrated into their original EtherCAT Master system. Advantech AMAX-5000 EtherCAT Slice I/O has a similar compact form factor as their previous I/O solution. After customer testing, the AMAX-5000 system successfully replaced their original solution and ensured even better quality print results.

Project Implementation

- AMAX-5580: EtherCATController

- AMAX-5081: TTL Encoder Module

-

AMAX-5056T: Timestamp DO Module

-

AMAX-5051T: Timestamp DI Module

System Diagram

Conclusion

Advantech provided a total control solution for their machine. However, migrating the entire solution was challenging and time-consuming so the strategy was to migrate the entire system step by step. The first step was to replace the EtherCAT I/O system which required compatibility testing to run with customer’s existing XFC system.

Advantech’s AMAX-5000 series not only integrated seamlessly with the customers’ control system, but also achieved better performance than their previous solution. The customer was also satisfied with the solid technical support they received which made for a successful migration.

-25/AMAX-5056T_9_82x8220200720174341.jpg)

-25/AMAX-5081_W20210603164814.jpg)

/AMAX-5580_0220200304191460.jpg)

/AMAX-5051T_3220200214191859.jpg)