Building AOI Technology to Accelerate Yield in Precision Manufacturing

3/6/2023

Introduction

Location: Japan

Automated optical inspection (AOI) technology is widely used in the precision manufacturing of electronics such as flat-panel displays, semiconductors, and printed circuit boards (PCBs). These products involve thousands of densely crowded joints and micro components that must be precisely installed. However, with technology becoming smaller and more complex, manual visual inspections are no longer adequate for quality control.

To provide a dependable solution for mass-production product inspections, many manufacturers have turned to AOI technology. AOI involves using machine vision to scan products and identify missing parts, short circuits, or poorly soldered joints. With the integration of additional devices such as robotic arms and CCD cameras, AOI systems can now very accurately identify tiny product defects with minimal failure rates.

For this project, a leading provider of image processing and automated inspection solutions required a high-performance platform to function as the server for AOI applications. In addition to AOI equipment for inspecting glass substrates, thin film, and silicon wafer surfaces, the company offers customization according to specific environments and production line types. For this reason, they needed a cost-effective platform that could be easily developed for diverse manufacturing sectors.

Solution Requirements

Solution Description

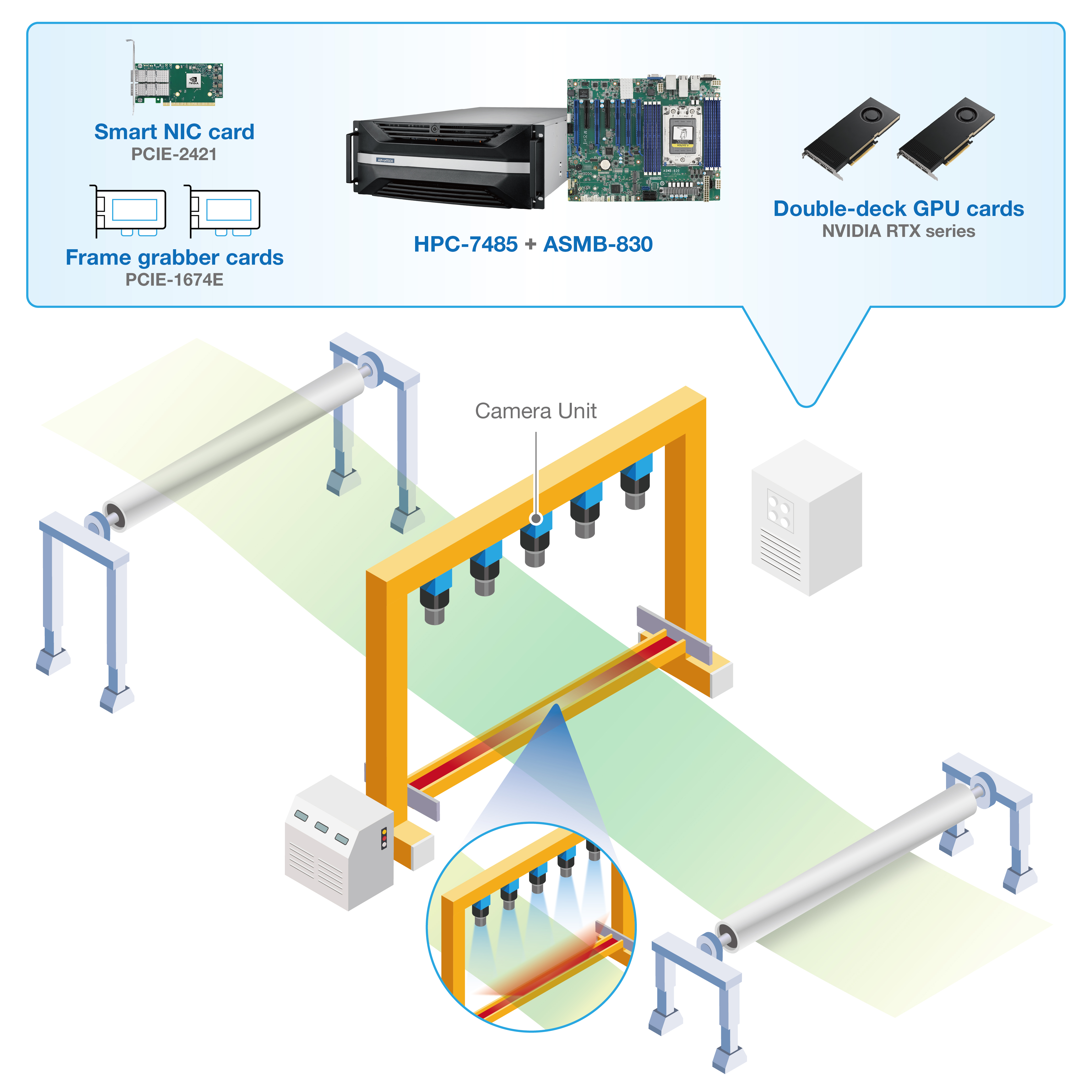

Advantech’s solution comprised its HPC-7485 4U rackmount server chassis with ASMB-830 AMD® EPYC™ ATX server board and Micron DDR4 DRAM memory. Designed to help manufacturers control and track data across processes, the ASMB-830 server board is powered by an AMD® EPYC™ 7003 series processor that supports wide operating temperature and up to five PCIe x16 and two PCIe x8 linkups to GPU cards, NIC cards, or other expansion cards.

To facilitate the processing of high volumes of data, the platform was equipped with two NVIDIA RTX series dual-slot graphics cards, two frame grabber cards, and one Advantech PCIE-2421 smart network interface (SmartNIC) card. The two dual-slot GPU cards support video/image analysis and AI inference, while the two frame grabber cards facilitate image capture for in-line inspections, and the SmartNIC card with dual-port 100GbE Ethernet ensures high-speed networking and data transfers. Moreover, with the provision of multiple expansion slots for integrating various capture and control cards, the solution can be flexibly configured to support several functions simultaneously. The high computing power provided by the AMD® EPYC™ 7003 series processor enables improved motion control and detection efficiency, as well as increased sensitivity and precision for inspecting objects of different size. Meanwhile, Micron’s DRAM technology boosts memory density, which optimizes overall machine vision performance, energy consumption, and operational reliability.

System Diagram

Benefit

- Industrial server-grade platform provides powerful image processing capabilities

- AI machine vision increases the efficiency and accuracy of quality control processing

- Supports remote maintenance and can be flexibly upgraded according to customer requirements

- Compatible with a wide range of frame grabber cards, motion control cards, and NIC cards.

- AOI technology reduces waste, lowers production costs, and maximizes product yields

Why Advantech

Advantech’s HPC-7485 + ASMB-830 solution not only deliver the necessary power for AOI, but also support flexible customization for diverse applications. In addition to high-performance computing, Advantech provides flexible technical support and a product longevity of up to five years. Advantech products allow solution providers to develop breakthrough innovations that meet both current and future AOI needs.

Industrial Quotient (IQ) Partner - Micron

Micron is an industry leader in innovative memory and storage solutions transforming how the world uses information to enrich life for all. With a relentless focus on our customers, technology leadership, and manufacturing and operational excellence, Micron delivers a rich portfolio of high-performance DRAM, NAND and NOR memory and storage products through our Micron® and Crucial® brands. Every day, the innovations that our people create fuel the data economy, enabling advances in artificial intelligence and 5G applications that unleash opportunities — from the data center to the intelligent edge and across the client and mobile user experience. To learn more about Micron Technology, Inc. (Nasdaq: MU), visit www.micron.com.

-25/SKY-640V2_Front-left-_Square20201117152448.jpg)

-25/ASMB-830_01--_Square20220225182058.jpg)

-25/ASMB-831_0120221123165624.jpg)