AI Optical Sorting and Classification in Coffee Bean Processing

4/21/2023

The Challenges for The Quality of Coffee Beans

To ensure the quality of coffee beans for international trade, they must undergo a screening process to detect issues such as discoloration, fermentation, mold, insect damage, and broken or chipped shells before roasting. However, manual sorting is laborious and prone to errors caused by fatigue, resulting in inconsistent quality. Advantech offers AI-powered solutions for coffee producers to analyze and sort beans based on various characteristics throughout the entire supply and value chains. These technologies include an optical sorter and quality classification system that leverage real-time AI inspection to enable non-invasive and efficient inspection. Furthermore, these technologies can be widely applied to the agricultural industry.

Globally, coffee once ranked second only to crude oil in commodity trading. Its popularity as a means to increase energy levels or stay awake has made it a daily staple for millions of people, creating a huge market. Coffee beans are often referred to as the “black gold” of agriculture because of their value. The flavor of coffee is affected by numerous factors, but the quality of the beans is the most crucial factor.

A longstanding problem is lack of consistency in quality of agricultural products. Currently, there is no large-scale method that uses artificial intelligence to assess crop quality in the industry. Even crops without visible issues like ruptures, leaks, or discolorations can be difficult to assess in a short period of time, since bruises or other damage may be hidden beneath the surface. This makes it challenging to maintain quality, as symptoms of bruising may only appear later.

Traditionally, sorting green coffee beans has been done by hand, which is a slow, tedious, and error-prone process. To address this challenge, the industry needs fast, comprehensive, and non-invasive detection methods. Fortunately, recent advancements in multispectral imaging (MSI) and machine learning have greatly expanded our capacity to sort in real time.

Now, with AI-powered inspection and sorting, for the first time, coffee producers can separate beans in greater volumes at speeds far exceeding traditional methods of mechanical separation, which required roasting and tasting to evaluate the quality. By using the AI Optical Sorter, coffee producers can sort uniform batches according to strict specifications, enabling them to consistently deliver higher quality blends.

System Requirements

In today’s market, there is a growing demand for efficient and accurate methods to select the best coffee beans for brewing premium coffee. Coffee beans of the highest quality are distinguished by color, shape, size, and morphology. This is where an automated optical inspection system using artificial intelligence is highly beneficial. By utilizing a data-driven algorithm, it becomes possible to train the system to classify objects accurately. This, in turn, enhances the quality inspection process and reduces the need for traditional inspections, resulting in significant cost and time savings. To implement such a system, there are some requirements:

- High-performance CPUs and GPUs for image acquisition and processing

- An AI-based automated optical inspection system for classification and analysis

- A tailored algorithm for determining object quality and type

- Technology to process and analyze images to meet morphology requirements

System Description

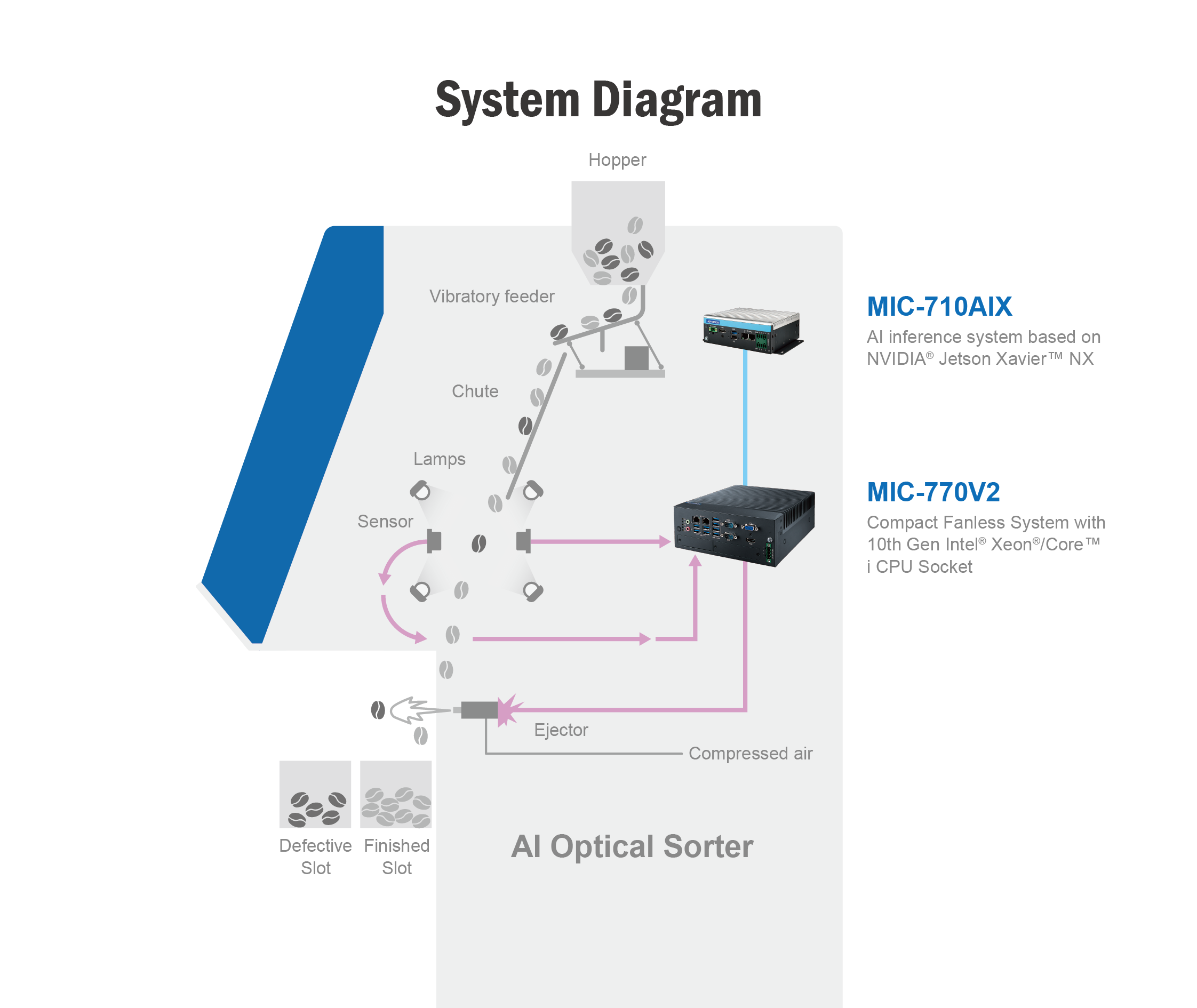

The AI Optical Inspection solution consists of a controller called MIC-770V2, which is fanless and x86-based. It comes with an integrated CameraLink frame grabber and camera, as well as lighting, sensor, and ejector modules. The CameraLink camera operates at high speeds, capturing images of coffee beans as they move through the feeder. This significantly speeds up the sorting process. The images are then transmitted to the MIC-710AIX which runs on the NVIDIA Jetson Xavier NX. This system segregates batches of beans, identifying specific types and superior quality using AI. Overall, the AI Optical Inspection solution is designed for high-throughput and non-destructive screening of coffee beans to select for specific quality traits.

Project Implementation

- MIC-770V2 controller with CameraLink frame grabber

- Camera, lamps, sensor, and ejector modules

- MIC-710AIX built on NVIDIA Jetson Xavier NX

Why Advantech AI Solution

Advantech's AI-powered optical coffee bean sorter and quality classification technologies provide coffee producers with a powerful and robust set of tools for analyzing and sorting a wide variety of attributes throughout the supply and value chains. This leads to an improvement in quality and revenue while adhering to strict quality guidelines.

Sorting technologies can be customized to meet the specific sorting and processing needs of the customer, allowing them to take advantage of each machine's unique features for optimal efficiency and performance.

Fanless systems such as the MIC-770V2 and the MIC-710AIX are ideal for food industry factories. The MIC-770V2 can be integrated with add-ons and control interfaces such as COM and DIDO to control devices. The MIC-710AIX, equipped with the powerful NVIDIA Jetson Xavier NX, provides industry leaders with faster and more efficient production methods. Systems based on these technologies can significantly increase processing capacity, particularly when using AI-based quality control methods.

-25/MIC-710AI_Front-left_P-(1)20240126143718.png)

-25/MIC-710AI_Front-left_P-(1)20240126143138.png)

-25/MIC-71120240411132903.png)

-25/MIC-711-ON_0320230517094751.jpg)