Advancing Automotive Leaf Spring Manufacturing through Smart Manufacturing

1/1/2024

In the world of automotive manufacturing, precision and efficiency are paramount. With complex bills of materials (BOM) and multi-step assembly processes, any missing part or material can bring the entire production line to a standstill. To tackle this challenge, automotive manufacturers have embraced lean manufacturing systems enhanced by manufacturing automation and industrial computing, aiming to eliminate waste and optimize production processes. An automotive leaf spring manufacturer, THACO INDUSTRIES’ corporation with TECHPRO and Advantech in the recent digital transformation project sets a very good example.

Bridging the gap between IT and OT

Automation has already revolutionized the automotive industry, but the concept of smart factories takes it to a whole new level. While robots excel in repetitive tasks, their rigid nature and lack of flexibility create isolated systems on the shop floor. Hence, bridging the gap between information technology (IT) and operational technology (OT) by improving connectivity is often the biggest challenge for mechanical processing factorys' path to smart manufacturing.

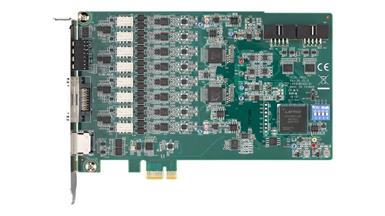

To tackle this challenge in THACO INDUSTRIES's project, TECHPRO and Advantech joined hands to offer IoT sensors, gateways, and edge devices for data acquisition, as well as MES, OEE, and FEMS solutions for production management, data visualization and analysis. They also provided industrial monitors, tablets, and embedded computers for the workstation. By harnessing the power of IoT, automation, and predictive analytics, TECHPRO seamlessly integrates and harmonizes the various elements leaf spring manufacturing through customization services.

Advantech's iFactory/OEE solution enables real-time monitoring and data visualization of the production equipment, allowing visibility of day-to-day operations through a visualized dashboard. Based on THACO INDUSTRIES’ specific requirements, TECHPRO created OEE formulas for each production stage and data visualization tailored to the mechanical processing factory.

Based on real-time data obtained from sensors and edge devices, Advantech's iFactory/FEMS solution allows the factory to monitor electricity and gas consumption information for energy management. Mr. Nguyen Dinh Hiep, CEO of TECHPRO, pointed out that the iFactory/FEMS is integrated with TECHPRO-MES solution so that the energy consumption of each work order can be accurately evaluated for optimizing the production cost and planning.

During the project implementation, THACO INDUSTRIES reviewed the leaf spring production process and helped the factory simplify the process from 13 steps to 10 steps, increasing production efficiency, reducing the workload, and leading to a more logical data flow and smarter information presentation.

Transforming into a data-driven smart factory

After project implementation, the IT and OT integration raised the automation rate from 25% to 82%. The productivity increased from 6,000 tons in 2018 to 9,000 tons in 2020. Mr. Nguyen Dinh Hiep stated, “The factory's management team informed us that not only did the number of employees required for each shift decrease, but also the production of leaf springs increased and the production cost was reduced.”

Also, the digitalization of the quality control process and equipment maintenance played a vital role in the success of this project because it allows them to access digital reports from TECHPRO-MES, rather than manually filling in production and maintenance-related information. This has simplified data collection while saving time and preventing data omissions. The OEE real-time data dashboard can also be accessed from both the situation room and the workstation, aiding the factory in obtaining meaningful insights into equipment utilization, production performance, and product quality, as well as enabling predictive maintenance, which alerts workers when to fix equipment before costly breakdowns occur.

The total solution co-created by TECHPRO and Advantech allows THACO INDUSTRIES to transform into a smart factory, where data-driven decision-making, real-time monitoring, and intelligent automation work in perfect synergy. With this innovative solution, the automaker can unlock the full potential of their production lines and achieve unprecedented levels of efficiency, quality, and profitability.

Case Study Benefits

- Gaining meaningful insights into equipment utilization

- Real-time monitoring of production capacity and quality

- Optimizing production planning and material management

- Enabling product traceability

Quote: “The iFactory/FEMS is integrated with TECHPRO-MES solution so that the energy consumption of each work order can be accurately evaluated for optimizing the production cost and planning.” - Nguyen Dinh Hiep, CEO of TECHPRO

WISE-IoT Magazine – Intelligent Factory: Transformation the Global Manufacturing Landscape with IoT

Advantech has remained committed to collaborating with global partners. Together, we strive to develop solutions that facilitate the rapid digital transformation of manufacturing while boosting competitive advantage.