Learn more about Advantech IPC by success stories

12/1/2022

Industrial IoT is the best pathway toward digital transformation and maximizing data value in your industry. By 2025, Gartner predicts 70% of enterprise-generated data will be created and processed outside a traditional data center or cloud. The volume of data generated from sensors and endpoints is forcing enterprises to deploy edge computing solutions that take advantage of this precious resource.

Advantech as the world's No.1 Industrial PC (IPC) provider, is dedicated to IIoT and edge computing solutions. We offer a comprehensive range of edge computers in a variety of form factors with high computing power and remote management, to support the quick development of smart machine automation, machine vision, and edge AI applications.

1. How to choose the right HMI solution based on your application?

In the production lines of smart factories, different sensors are built into manufacturing equipment to automatically check product quality and capture device data. HMI devices aggregate data and simply process the information for a more efficient and productive system. Additionally, according to the needs of cloud applications and intelligent manufacturing, factory management and production decisions are more reliant on visualized control platforms. HMIs simplify and visualize data to make it intuitive to understand at first glance. Industry 4.0 transformation integrates IT and OT systems to share and use the management data in MES or ERP systems, and the production data in production equipment to achieve a more flexible and efficient manufacturing process.

2. Yogurt Container Maker Uses Visual Inspection System to Increase Quality Control

The Advantech vision inspection solution formed an integral part of the client’s ability to consistently deliver high-quality yogurt products to market while minimizing total cost without compromising on quality. High-quality food container manufacturing can easily be achieved through the optimization of the manufacturing process, whereby controls are put in place to detect and eliminate any defective products. By implementing an automatic inspection system to inspect each container, the whole manufacturing process was streamlined. The inspection system also brought about the means to identify equipment issues. These could be tracked directly to the source and quickly resolved to prevent trickle-down problems. A secondary benefit came from the accumulation of data. The Advantech solution provided timed stamped images of defects for further analysis and refinement.

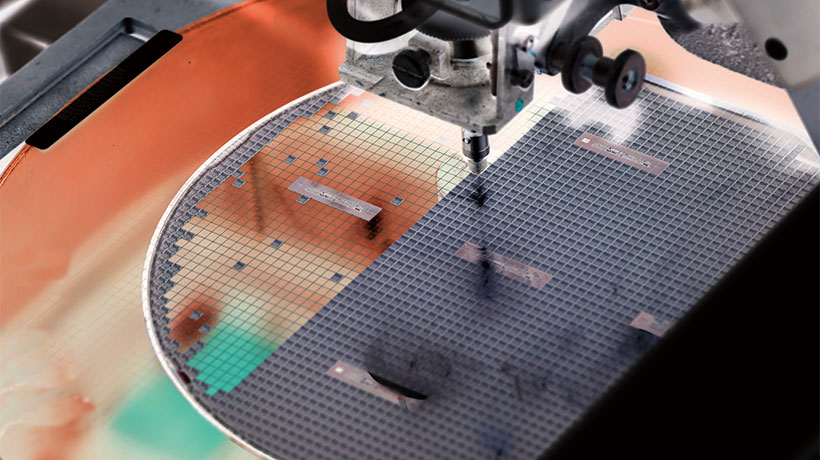

3. Vision Positioning Solution for Wafer Cleaning

Advantech vision positioning solution greatly shortened the time for wafer cleaning from seconds to milliseconds (ms) and allowed precise pick and placement that avoided wafer damage. The solution comprised of a high computing vision analysis platform for 20.0 megapixel PoE industrial cameras that performed high-speed wafer dimension calculations and center position measurements. The intelligent vision analytic solution helped the IC manufacturer transform their wafer cleaning process into a smart optimized process. This helped them continuously manage and improve production yield rates and improve efficiency to maintain their premier position in the semiconductor manufacturing industry.

4. Maintaining the Automotive Industry’s High-Quality Standards Using Smart Systems

The smart solution for the auto manufacturer entails the use of an industrial computer to perform the automated test and visual inspection of workstations to prevent product defects and reduce issues related to manual operations, such as errors and low efficiency, in order to improve production quality, while accelerating inspection speeds to prevent work station bottlenecks at inspection points. The durability and 24/7 operation of the system minimized the downtime in testing and visual inspection stations, which resulted in lowered equipment failure. Additionally, the transition to a greater reliance on Advantech products allowed it to implement global standards more effectively across its equipment infrastructure.

5. Developing Cost-Effective Smart Solutions for the Transportation Industry

Advantech partnered with SAM to provide DFSI Smart transportation by using Edge AI Inference Computers embedded in systems and similar environments. The adoption of the solution proved that operational efficiency could be achieved while lowering installation costs and proved the overall convenience of working with Advantech-based products. The project focused on developing a modern toll collection system that included the following criteria: Resistance to climate conditions - It was essential that the system could withstand environments with varying humidity and temperature conditions. Easy to maintain. Durable and cost-effective. Adaptable - It was important that industrial-grade technology continues to support legacy technologies such as ISA cards and various other options.

6. Conveyor Health Management Innovation for Continuous Monitoring

The condition monitoring system (with integration into the cloud and manufacturing system software) provides information to operations and maintenance personnel by examining input data from each sensor point in real time. Using advanced analytics, acquired data that fails pre-programmed tolerances and modes, trigger alarms, and notifications for system maintenance to be carried out. It allows failures to be predicted long before they occur, allowing for planned maintenance and servicing, preventing disruption, and overall cost associated with bearing failures.

7. Modular AI Defect Inspection Solution Makes Semiconductor Equipment Upgrades More Efficient

Artificial Intelligence (AI) technology can make up for the shortcomings in Automatic Optical Inspection (AOI), however, it requires a large number of computing resources. It depends on the pros and cons of the hardware equipment to give full play to their functions. With a combination of multiple MIC series products, Advantech provides a modular solution for defect detection AI applications, which not only have high efficiency and stable performance, but also enable adding of computing resources through a plug-in approach. This allows System Integrators to configure hardware according to the current needs of the project, while providing convenience for future expansion. End customers can also benefit from this cost-effective solution to realize AI applications as soon as possible.

8. Multi-Angle Vision Inspection and 6-Axis Smart Robotic Integrated Solution for Automotive Manufacturing

Robots are key pieces of equipment that turn a standard factory into an advanced manufacturing center as they can be dynamically configured and upgraded to fulfill dedicated EV manufacturing processes. To expand the new production line had to be equipped with an advanced robotic platform that was capable of handling high-speed vision processing, data transmission, and multiple channels of digital I/O for data collection. The IPC solution to support the manufacturing needed to enable a 6-axis robot to achieve multi-angle automated visual inspection (AOI) at each point in the manufacturing cell where the four 6-axis robots were installed.

9. Highly Integrated IPC Solution Selected as Universal Platform by Worldwide Manufacturers

In order to produce a wide range of high-quality fastening products and merchandise worldwide, global manufacturers need to upgrade their systems for better production efficiency. For fulfilling this they need a high-end IPC solution that could be widely deployed on their production lines across all their manufacturing sites worldwide. Advantech's solution features high computing power and legacy compatibility, and also can be a modularized design to easily change and upgrade add-on cards (motion, frame grabber, GPU, etc.) for new functions and applications that global manufacturers required.

.jpg)

-25/AIMB-708_2----20220516165639.jpg)

-25/ACP-2020G_Front-left-_Square20201209190541.jpg)

/MIC-75M40_S20160308100844.jpg)

/ACP-4020_Front left _S20170825180748.jpg)

/ACP-2020_Front left_B20170825115752.jpg)