A Solution for Screw Inspections

7/23/2018

Introduction

Developments and upgrades in electronics industries have coincided with an increase in the usage of electronic screws, which has led to greater demand for high-quality screws.

System Requirements

System Description

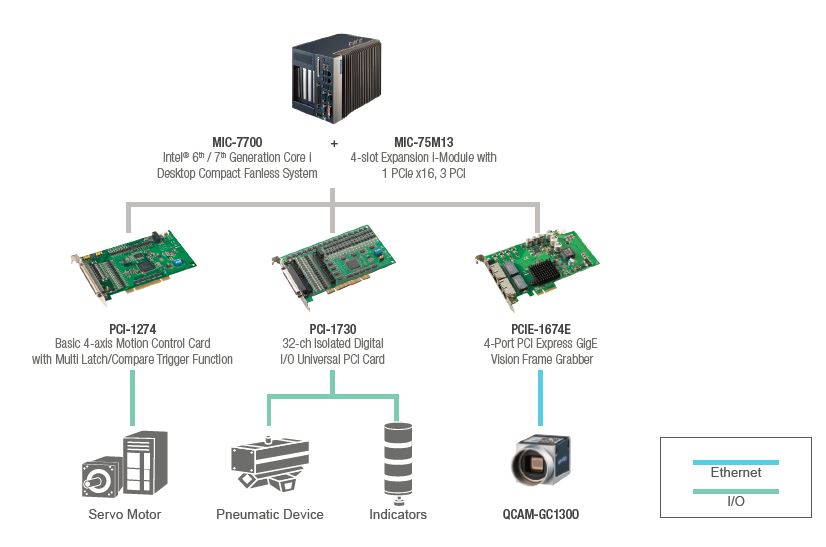

The screw inspection platform was based on the modular IPC MIC-7700 with a MIC-75M13 4-slot expansion i-Module, the system was able to manage multi-tasking between precise motor control and high-accuracy visual inspections. Installed in the system was a PCI-1274 4-axis DCP-based motor control card for connecting to servomotors.

Project Implementation

- MIC-7700 / MIC-75M13: Intel® 6th / 7th Generation Core i Desktop Compact Fanless System / 4-slot Expansion i-Module with 1PCIe x16, 3 PCI

- PCI-1274: Basic 4-Axis Motion Control Card with Multi-Latch/Comparative Trigger Function

- PCI-1730: 32-ch Isolated Digital I/O Universal PCI Card

- PCIE-1674E: 4-Port PCI Express GigE Vision Frame Grabber

- QCAM-GC1300: 0.3~15-MP PoE Industrial Camera

System Diagram

The PCI-1274’s comparative trigger function cut costs for the customer by allowing them to shorten their program development time. In addition to the benefit of adopting a total solution, this saved system integration time and accelerated the customer's development speed.With our team of application engineers providing technological support, we were thus able to satisfy this customer’s CCD needs.

Conclusion

The PCI-1274’s comparative trigger function cut costs for the customer by allowing them to shorten their program development time. In addition to the benefit of adopting a total solution, this saved system integration time and accelerated the customer's development speed.With our team of application engineers providing technological support, we were thus able to satisfy this customer’s CCD needs.