Cost-Effective Audio Extraction Solution for Vehicle NVH Testing

9/16/2024

Project Introduction

Noise, Vibration, and Harshness (NVH) is a set of crucial parameters for describing the quality of vehicle design and engineering. A vehicle NVH Analysis comprises tests on three major parts: engine, car body and undercarriage. NVH testing is a key factor in deciding the comfort for passengers and drivers in the car. New-generation electric vehicles lack engines and the associated low-frequency noise, but they are susceptible to high-frequency tonal noise produced by their electric motors.

Statistics have revealed that one-third of vehicle failures are associated with NVH issues, and large auto companies spend nearly 20% of their R&D budget on solving NVH problems. As for electric vehicles, the objectives of NVH improvements are not just for troubleshooting but also for upgrading driver experience. The exclusion of noise from electric motors is one of the aims of an electric car NVH test.

System Requirements

Noise identification is a crucial part of an NVH test system, which uses directional microphones as sensors in acquiring noise signals during equipment operations and analyzes the acquired data so as to identify the source and cause of noise generated by the equipment.

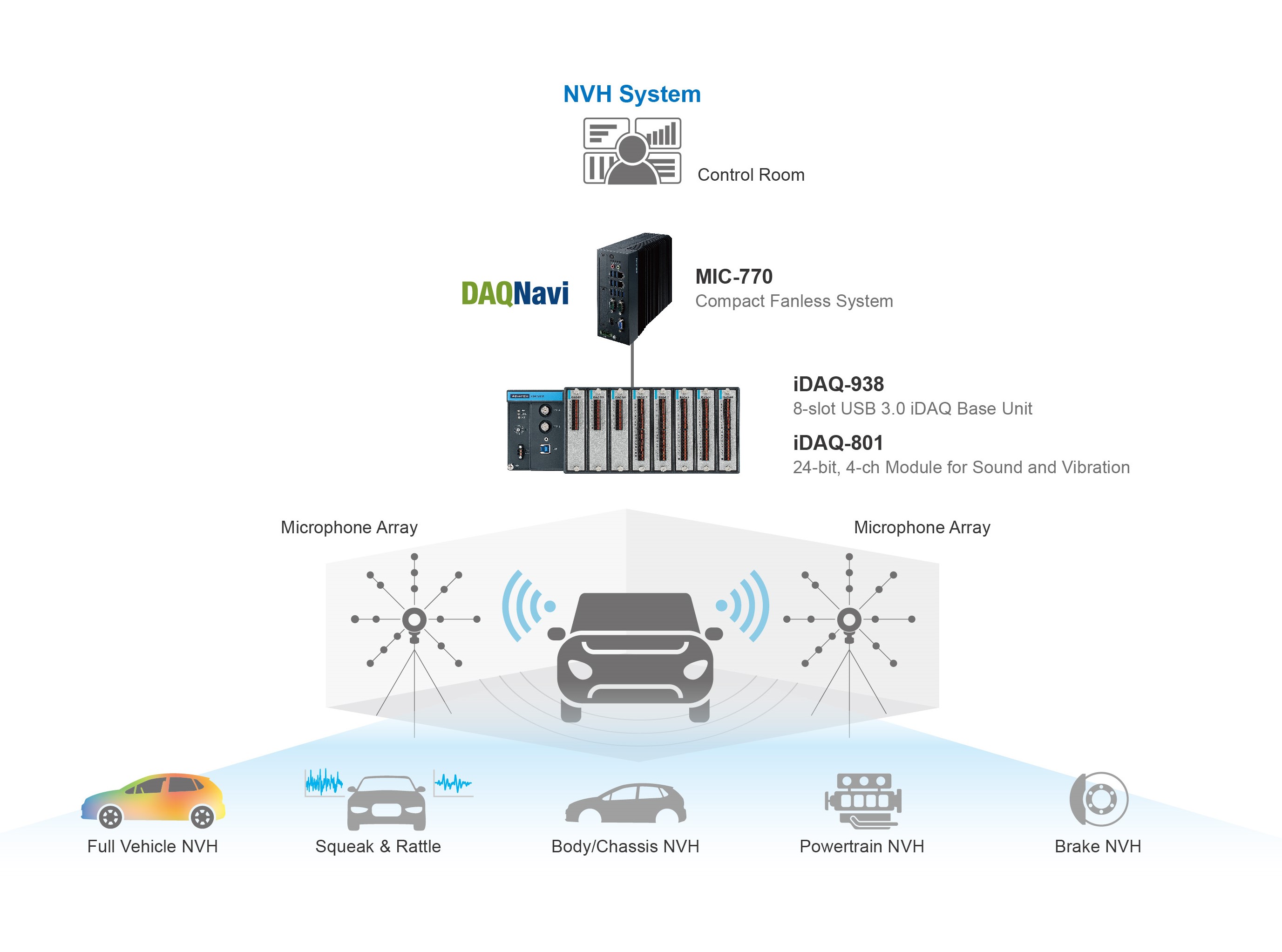

Such a noise identification system is comprised of three major components: an array of industrial microphones (amplifiers), dynamic signal acquisition (DSA) system (iDAQ-934+ iDAQ-801 x 4), and software development tool (DAQNavi) for noise analysis and identification.

The microphone array is composed of 16, 24 or 32 sets of microphones to acquire signals from the sound field and identify the sources of signals and their decibel levels, as this Advantech application case required.

Advantech IDAQ-934/938 intelligent DAQ chassis provides 4 or 8 expansion slots to accommodate Advantech iDAQ-801 data logger modules (4-ch sound & vibration DAQ modules) for flexible system configuration in accordance with the number of microphones required for an application. In addition, Advantech IDAQ-93x series provides powerful synchronization for modules in a chassis and for multiple chassis as well, ideal for synchronized signal acquisition from a large array of microphones. The synchronization feature, when combined with the use of a camera and visual software, can quickly identify the source of sound signals and their decibel levels.

Additionally, Advantech’s MIC-770 enhances system functionality with its ruggedized and high-performance design. It facilitates real-time transmission of information to the backend, allowing technicians to efficiently conduct information analysis and troubleshooting tasks. Furthermore, MIC-770 ensures uninterrupted operation with its support for 24/7 long-term stable performance, thereby maintaining overall system efficiency.

Project Implementation

- MIC-770:Compact Fanless System with 8th Gen Intel® Core™ i CPU Socket (LGA 1151)

- iDAQ-938:8-slot USB 3.0 iDAQ Base Unit

- iDAQ-801:256kS/s/ch, 24-bit, 4-ch iDAQ Module for Sound and Vibration

- DAQNavi:A data acquisition software to enable edge intelligence for your DAQ devices

System Description

In this automobile application case, Advantech provided MIC-770 high-performance fanless IPC together with iDAQ-938 DAQ chassis, IEPE signal acquisition module iDAQ-801, and software development tool DAQNavi SDK that contains various APIs for meeting different needs in NVH system development. The system uses iDAQ-801 modules to connect with IEPE microphone sensors and provide a control console for acquiring vibration data in fulfilling NVH & Acoustics test and measurement.

Advantech iDAQ-801 is a modularized data logger providing 24-bit 216 kS/s sampling, acquiring IEPE signals with a built-in 4 or 10 mA electric current. The iDAQ-934/938 chassis uses USB ports to transmit acquired data, sparing users the need to open the chassis to install a data transmission interface card. Furthermore, the signal synchronization features embedded on the chassis baseboard can realize simultaneous sound signal samplings from a great number of microphones.

As for software offering, DAQNavi is a software development kit designed for Advantech DAQ products, with which users can establish a data acquisition system quickly via a bunch of easy and useful tools including intuitive wizards, ready-to-use application templates and sample code, library, and utility software, aimed to reduce time-to-market for developers.

System Diagram

Conclusion

Advantech iDAQ-934/938 DAQ chassis provides 4 to 8 expansion slots for housing iDAQ-801 DAQ modules in supporting various types of industrial microphones, which will allow system integrators to quickly build an NVH signal acquisition system according to their specific needs. Meanwhile, Advantech DAQNavi SDK paired with fanless embedded system, MIC-770, can support a variety of programming languages to allow users to choose a language they are most well-versed in for developing a system quickly and smoothly. No matter for the creation of a brand new NVH system or for an upgrade of an existing system, Advantech, with a complete array of iDAQ products, is able to deliver a custom solution that most fits customer needs with a flexible configuration.

/MIC-770_Side _S20190325104539.jpg)