Intralogistics 5.0: Developing and implementing state-of-the-art AGV/AMR AIUT solutions

10/20/2023

Abstract

AGV systems perform automatic pickup, transportation and storage of goods, following pre-defined pathways, however, there are challenges with the availability and deployment of state-of-the-art AGV technologies. The challenges include the availability of experienced suppliers with a comprehensive and certified product portfolio. A well-rounded solution will inevitably lead to increased automation, ease of implementation, decreased labor costs, higher productivity, and lowered total manufacturing costs.

Partner: AIUT l Region: Poland

Introduction

Automated Guided Vehicle (AGV) systems are typically used in the manufacturing industry for increased efficiency and productivity. More specifically, AGV systems are used to efficiently transport and move items in production, manufacturing centers and warehouses, which replaces the need for manual handling, eliminating human error, and by result – increasing safety of the workplace and significantly reducing costs. These systems perform automatic pickup, transportation and storage of goods, following pre-defined pathways, however, there are challenges with the availability and deployment of state-of-the-art AGV technologies. Predominantly the challenges include the availability of experienced suppliers with a comprehensive all-in-one system efficient technologies and a certified product portfolio. A well-rounded solution will inevitably lead to increased automation, ease of implementation, decreased labor costs, higher productivity, and lowered total manufacturing costs. An advanced intralogistics system by AIUT will deliver just that.A system operated by AIUT Formica Autonomous Mobile Robots (AMRs) - uses natural navigation to automate the internal transportation of goods. Explore AIUT’s solution enabled by Advantech.

Project Requirements

The project of providing AMRs to the market was carried out by AIUT. This flexible and comprehensive intralogistics system, where automated transportation of goods is provided by a fleet of AIUT Formica mobile robots, has been customized by AIUT to meet the customer's expectations.AIUT is a global provider of technologically advanced solutions in automation and robotization of production processes, IT, and the Industrial Internet of Things (IIoT). The company also automates and optimizes production processes and implement comprehensive projects for clients worldwide.The automated mobile robots increase logistics efficiency, automate internal deliveries, ensure a stable production process and reduce operating costs. The company’s AMRs, named as the Formica family, work to improve processes, and consequently the operation of production plants. The 2 types of AMRs are: Formica 1, an intelligent transport vehicle designed to work continuously in a dynamic environment streamlining and improving industrial processes using cooperating robots; Formica 2, a self-propelled, intelligent mobile robot developed for transporting Euro-pallets with a load of up to 1500 kg weight and the function of ground-level self-loading.To accomplish this project, one of the major requirements for AIUT was for hardware systems (including fanless computers) with Underwriter Laboratories (UL) certification for their AMR systems. In addition, it was critical to have an experienced supplier with a wide-ranging reliable product portfolio to simplify product sourcing and to minimize the need for multiple distributors. The requirements are shown below:

- Multi-region certified components, CE, UL, etc.

- Comprehensive product portfolio with maintenance and service availability on a global scale

- High-quality customization flexibility

- Flexibility and global scalability across multiple market segments

System Description

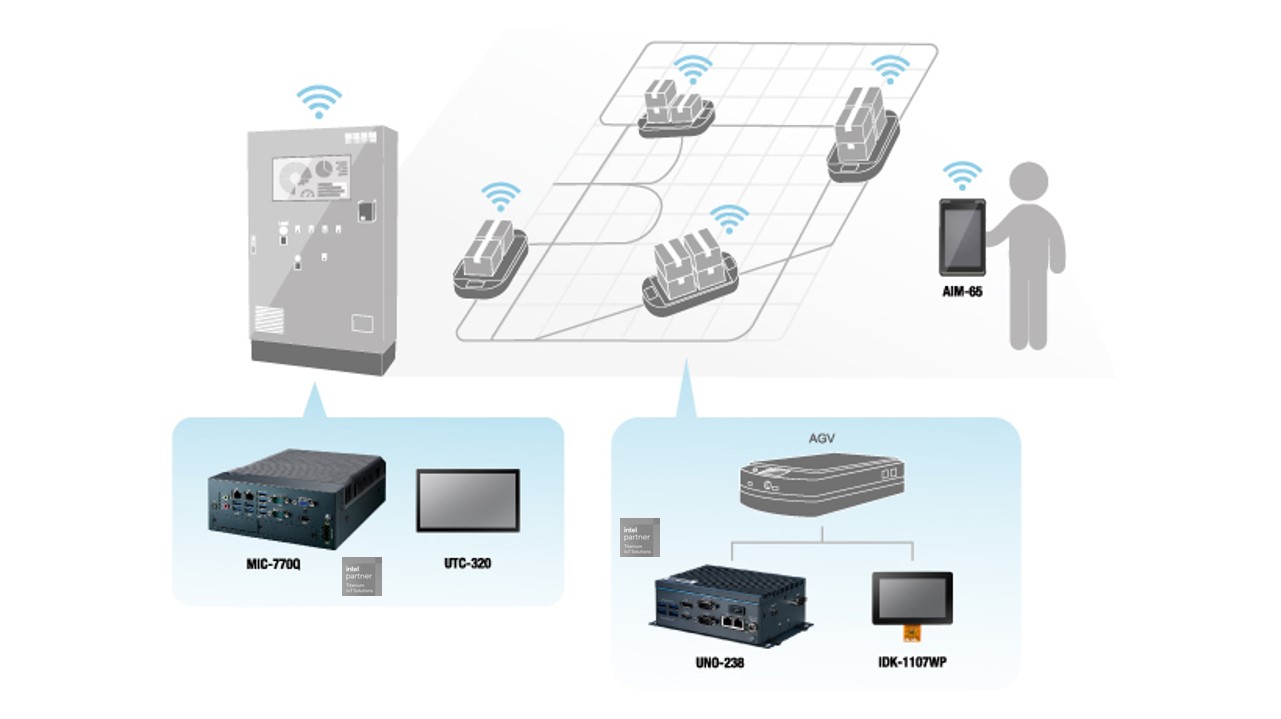

The AIUT AMR solution entailed Advantech’s MIC-770Q, IoT edge computer which comprises the software to control and monitor all vehicles within a manufacturing area. The MIC-770Q is a compact computing solution designed for high-performance 8th generation computing applications. The solution also included Advantech’s UNO-238 fanless system, a compact computing solution with 8th generation Intel® Core CPU, for reliable high-performance computing. In addition, the UNO-238 has an optimized mechanical design for easy RAM swapping, increased flexibility, and easy maintenance. In this solution, the UNO-238 computes and collects information about the AMR and sends it to the cloud either through Wi-Fi or LTE. The communication between the central unit and the AMR is continuous. Additionally, the MIC-770Q and UNO-238 exchange information regarding tasks, vehicle positions, and status. Furthermore, the AIUT AMR solution entailed Advantech’s UTC-320, which is used as an interface for the MIC-770Q to visualize the process and designate tasks to AMRs. The UTC-320 is a multi-purpose computing system with a touch-based LCD panel. The solution also incorporated Advantech’s IDK-1107W, an industrial display kit with touch screen capable of operating at different temperatures,an AIM-65, industrial tablet also by Advantech, used to check the status and operating parameters of selected AMR vehicles and connected by scanning the QR code on the vehicle. It is also worth highlighting that these technological components provided by Advantech all have UL certifications.

Project Implementation

- MIC-770Q: Compact fanless system

- UTC-320: 21.5" ubiquitous touch computer

- UNO-238: Compact IoT edge computer

- IDK-1107WP: 7" WVGA/WSVGA industrial display kit with touch solution

- AIM-65: 8" industrial tablet

Conclusion

As a result of the increasing need for improved efficiency and higher productivity in the manufacturing industry, state-of-the-art AMR systems have been developed and implemented to ensure ease of implementation, reduced labor cost, and enhanced automation.

In answer to industry demands , AIUT responded with state-of-the art AMRs as part of its intralogistics solution. To help this happen, Advantech provided a technological solution meeting the needs of AIUT, which entailed the provision of globally certified high performance hardware platforms. Furthermore, Advantech’s comprehensive product portfolio fostered ease of sourcing and the delivery of a framework required to expand product lines and markets worldwide. The AGV/AMR solution comprised Advantech’s MIC-770Q, UTC-320, UNO-238, IDK-1107W, and AIM-65, advanced and robust technological products used to control, monitor, visualize and manage the AGV/AMR systems.

Overall, the collaboration between AIUT and Advantech on an advanced solution led to cost and time savings resulting from a direct and seamless partnership. In addition, Advantech’s comprehensive products portfolio and multi-region certification contributed to AIUT’s transition from the regional North American automotive market to the wider global market within a few years.

-25/UNO-238_Front-left_Banner20210108191823.jpg)

/MIC-770_Side _S20190325104539.jpg)