Smart Factory Solutions for Tobacco Industries

2/24/2022

Bridge Manufacturing Generation Gap and Improving Operational Efficiency

Abstract

The decline in cigarette volumes has led to the pursuit of efficient supply chains. Advantech smart monitoring systems improve in-factory logistics management and equipment maintenance. The flexibility of the Advantech products allow a minimal hardware footprint, further minimizing requirements and maximizing production efficiency.

Partner: British American Tobacco | Region: Russia

Introduction

The continued decline in cigarette volumes around the world has highlighted the importance of efficient supply chains and the continual pursuit of optimized production processes. Even more so, there is a realization by the industry for greater emphasis on agile production facilities and the inclusion of Industry 4.0 to accommodate the diverse production requirements in order to offset existing difficulties related to market declines, legacy equipment usage, and the introduction of regulatory restrictions. For manufacturers faced with such threats to their operations, the ultra-efficient production line is seen as the opportunity for a changing industry.

System Requirements

British American Tobacco (BAT), a British multinational company that manufactures and sells cigarettes, tobacco, and other nicotine products, required a factory solution to automate their product control processes. From the transportation of the tobacco and cigarette paper to the placement on the cigarette machines to the packing conveyor, the process needed to be significantly automated to significantly meet quality control targets for the final product. They also required support for the continuous use of legacy equipment, such as relay-controlled cigarette machines dating back to the 90s and AMK servo drive systems, to sustain production levels at speeds of 8000 to 16000 pieces per minute. In short, it is a production target impossible without improved and precise quality measures at every stage of production. Furthermore, labeling requirements meant flexibility had to be incorporated for BAT to meet changing regulatory guidelines.

System Description

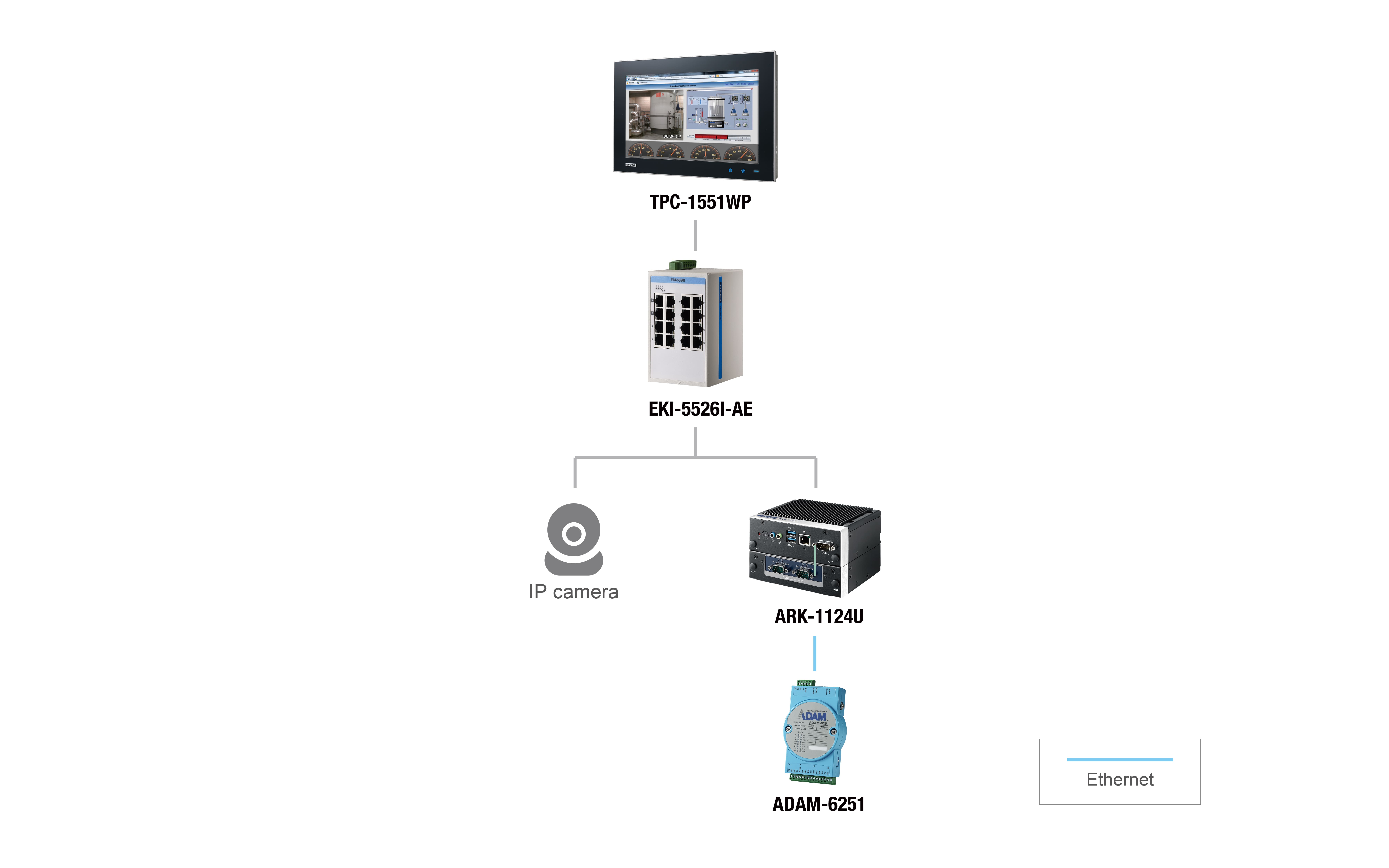

BAT and Advantech quickly set up a project to evaluate every stage of production and customize a solution for BAT’s unique case. The solution encapsulated the ARK-1124U and ADAM-6251 into a single system for data collection and analytics processing through a standard Ethernet interface. On the manufacturing floor, the networking framework was resolved using EKI-5526I-AE industrial switch to unify communication between the various subscribers on the production line. Designed for the rigors of an industrial environment, the EKI product lines function on standard 24V redundant power, operate without failure through vibration and high-temperature conditions, and can be easily mounted on DIN rails. The flexibility aspect of the solution came in the form of the TPC-1551WP, a thin client terminal specifically designed for a variety of applications. With the TPC-1551WP, Advantech’s smart solution provided the barcoding aspect necessary for the final requirement step.

Project Implementation

- ARK-1124U IoT gateway modular fanless box PC

- ADAM-6251 16DI Ethernet remote I/O module

- EKI-5526I-AE 16 FE unmanaged Ethernet switch

- TPC-1551WP thin client terminal

System Diagram

Conclusion

Without a smart factory solution, calculating production volume in a tobacco plant is error-prone and inefficient. Smart monitoring systems that can automatically communicate across the network and collect production data greatly improves in-factory logistics management and equipment maintenance. Combined with the use of networking devices, a smart factory solution can be developed to effectively transform the production of a factory. The leaders and experts at BAT determined that the use of Advantech’s smart factory solution allowed them to realize a complete system for the collection of data across the generational divide in their machinery. To further add, Advantech’s experience in the automation industry provided the flexibility for BAT to meet the barcoding requirements on all the products and meet governmental regulations. On top of the benefits from the smart factory solution, the modularity and flexibility of the Advantech products allowed BAT to capitalized on a minimal hardware footprint, further minimizing requirements and maximizing production efficiency.

/ADAM-6251_03_S20190730122942.jpg)