Working Toward Net-Zero Greenhouse Emission in the Semiconductor Manufacturing process with the Advantech UNO-148 V2 Controller

12/31/2024

Introduction

The semiconductor industry is embracing the challenge of reducing its environmental impact, aiming for net-zero greenhouse emissions through innovative solutions. This case highlights how integrating the Advantech UNO-148 V2 Controller, a cutting-edge industrial automation tool, empowers manufacturers to monitor chemical emissions, energy consumption, and operational efficiency. With real-time monitoring and process optimization capabilities, the UNO-148 supports the industry's transition to sustainable practices, aligning with global initiatives like the Paris Agreement. This case underscores the crucial role of automation and energy-efficient technologies in driving greener, more sustainable semiconductor manufacturing.

System Description

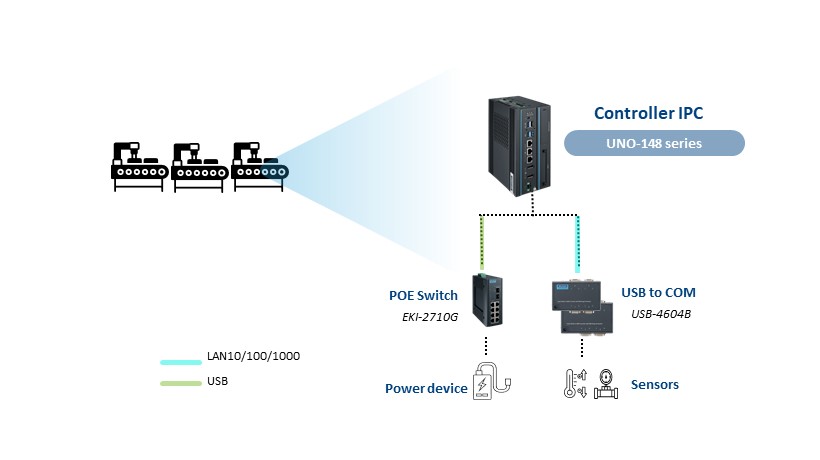

This semiconductor control system is built around the Advantech UNO-148 V2 controller, which integrates multiple monitoring devices and sensors via a PoE switch for comprehensive data collection and monitoring. The controller provides real-time tracking of operational status, energy consumption, and emission levels. Additionally, it uses a USB-to-COM converter to transmit data to serial communication devices, ensuring stable and precise control throughout the production process.

- UNO-148 V2Controller: Serves as the system’s central hub, connecting to the PoE switch and USB-to-COM converter. It provides essential data on equipment operational status, energy consumption, and emissions. PoE Switch: Supports real-time data transmission in the semiconductor

- PoE Switch: Supports real-time data transmission in the semiconductor industry, delivering essential data such as operational status, power consumption, and alerts. It ensures stability, real-time monitoring, and efficient energy management by providing network and power connectivity for system devices like IP cameras and industrial IoT devices, facilitating two-way data transmission over LAN.

- USB-to-COM Converter: Converts signals between USB and COM to allow precise environmental monitoring with sensors for gas, temperature, humidity, and current. It ensures stable production conditions by transmitting real-time data to the controller, which adjusts equipment parameters as needed.

Why Advantech

The Advantech UNO-148 controller, with its industrial-grade design and robust real-time monitoring capabilities, is particularly suitable for semiconductor equipment monitoring and energy management. Leveraging its stable system architecture, the UNO-148 accurately tracks equipment energy consumption, successfully reducing related costs by 20% for semiconductor manufacturers. This efficient control solution not only enhances operational efficiency but also significantly reduces greenhouse gas emissions.

- Industrial Design: Rugged, durable, and designed to operate in temperatures from -20 to 60°C, ensuring long-term, reliable usage.

- Compact and DIN-Rail-Compatible: Ideal for confined spaces in semiconductor racks.

- Front I/O Interface: Facilitates easy installation and operation within control cabinets.

- Modular Design: Provides flexible I/O expansion options for customers.

- Real-Time Technology: Equipped with dual 2500BASE-T Ethernet, supporting TSN technology to enhance network communication efficiency.

- AWS IoT Greengrass Certification: Strengthens data security and enables centralized data management and long-term storage.

- Comprehensive Solution: Advantech provides a complete semiconductor solution, including controllers, PoE switches, and converters.

Conclusion

The Advantech UNO-148 controller is a highly effective solution for monitoring semiconductor equipment. Its industrial-grade design and real-time monitoring capabilities enhance energy efficiency and reduce greenhouse gas emissions. This system enables semiconductor manufacturers to meet strict environmental standards, improve production efficiency, and ensure operational stability, while addressing the stringent real-time data monitoring and environmental management requirements in semiconductor manufacturing.

-25/UNO-148-V2_03--20240328182430.jpg)