-

Productos

Embedded Computing

- AIoT Software, Distribution & Services

- Application Focus Embedded Solutions

- Arm-Based Computing Platforms

- Computer On Modules

- Digital Signage Players

- Edge AI & Intelligence Solutions

- Embedded PCs

- Embedded Single Board Computers

- Fanless Embedded Computers

- Gaming Platform Solutions

- Industrial Display Systems

- Industrial Flash & Memory Solutions

- Industrial Motherboards

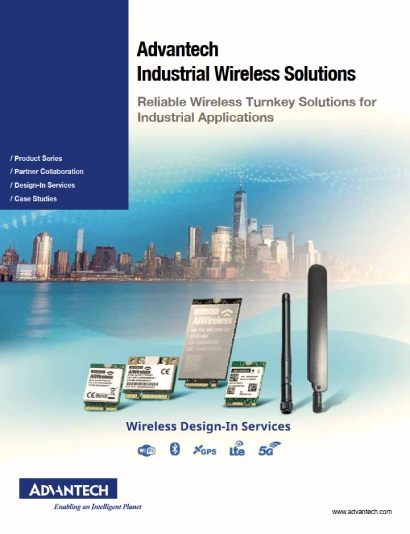

- Industrial Wireless Solutions

- Wireless ePaper Display Solutions

Applied Computing (Design & Manufacturing Service)

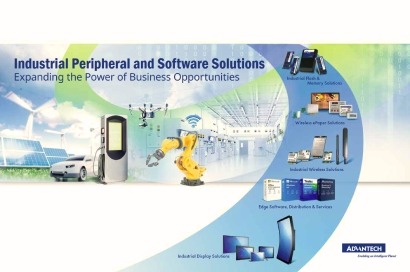

Industrial Automation & I/O

- Automation Controllers & I/O

- Certified Solutions

- Class I, Division 2 Solution

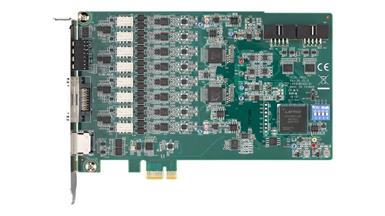

- Data Acquisition (DAQ)

- Embedded Automation Computers

- Gateways & Remote Terminal Units (RTUs)

- Human Machine Interfaces

- Motion Control

- Panel PC

- Power & Energy

- Remote I/O

- WebAccess Software & Edge SRP

- Wireless I/O & Sensors

Intelligent Connectivity

Intelligent Systems

- Box IPC

- CPCI & VPX

- Industrial Computer Peripherals

- Industrial GPU Solutions

- Industrial Motherboards & Slot SBC

- Intelligent Transportation Systems

- Modular IPC

- Rackmount IPC

Cloud, Networking & Servers

- Industrial, Telecom and Cloud Servers

- Network Interface & Acceleration Cards

- Network Security Appliances

- SD-WAN & uCPE Platforms

- WISE-STACK Private Cloud

Computer Vision & Video Solution

Intelligent Healthcare

- Carros de Enfermería Computarizados

- Computadoras Médicas

- Pantallas Médicas

- Sistemas Inteligentes de Energía

- Terminales de Info-Entretenimiento para Cuidado de

Intelligent Mobile Solutions & Logistics

Intelligent City Services & Retail

- All-in-One Touch Computers & Kiosks

- iCity Service & iRetail Solution

- POS & Tablets

- Signage & Edge Computers

Industrial Mounting (Stands/Arms/Workstations)

-

Soluciones

Soluciones

- Servicios

-

Socios

Business Alliance Partner

- Soporte

- Corporativo

- Contactarnos

Visit the Advantech Global website, or choose your country or region below.

Africa & Middle East

MyAdvantech Registration

Recursos

In the Resources section, you can catch up on information about industrial news, insights, and the latest technology from Advantech's point of view.

-

Porfavor, no seleccione más de 7 criterios de filtro

No matches found with your selected filters.

Please try again by resetting and choose other criteria.

¿Como podemos ayudarte?

About Advantech

Recursos

Soluciones

- Soluciones Embebidas y servicio de rediseño

- Energía y Servicios

- iFactory - Fábricas inteligentes

- iHealthcare

- iLogistics

- Servidores industriales para Telecomunicaciones

- Fabricación de Equipos Industriales

- Sistemas de transporte inteligente

- Servicios y soluciones de inteligencia de borde de IoT

- iRetail

- Soluciones de vídeo

- Design & Manufacturing Services

¡Podemos apoyarte!

¿Has tenido algún problema o duda? Cuéntamos y buscaremos la forma de ayudarte.

- © 1983-2024 Advantech Co., Ltd.

- Site Map

- Política de privacidad

- Do Not Sell My Personal Information

.jpg)