Intelligent edge computers easily integrate to run Artificial Intelligence and Machine Learning software for local solutions

Water/wastewater systems and remote pumping installations are spread throughout municipalities and across various neighborhoods, though not always visibly noticeable to residents. The ability to manage pumping and treatment systems remotely and monitor real-time operations is crucial to optimizing and protecting water supplies. Specifically, lift stations are a critical piece of a community’s wastewater treatment infrastructure, and effectively transport sewage over uneven terrain to primary treatment plants.

Pumping installations normally consist of one to three pumps and its associated control panels. Lift stations include a storage tank, referred to as a wet well, along with floats or sensors for controlling the pumps and maintaining safe levels of storm water or sewage. Any failure of components in these facilities can cause undesirable consequences, such as low water pressure in hydrants or hazardous sewer backups.

Remote Location and Monitoring Challenges

Larger municipalities may have hundreds of lift stations at work at one time; however, remote locations of most lift stations make real-time management and monitoring a challenge. Many facilities do not have remote monitoring at all; instead relying on rudimentary monitors, such as a blinking warning light on a pole and a sign for passersby to call for assistance. Other systems may have monitors connected to leased copper lines or dial-up phone lines, which notify operators of equipment failures.

Relying on passersby to monitor critical systems is far from reliable. Additionally, leased lines and dial-up options from carriers are either being phased out or becoming more expensive. Sophisticated municipalities may use private radio systems to monitor water operations, but these systems are expensive, need FCC licenses to operate, and require constant maintenance.

Modernizing Legacy SCADA Systems

To address these management and monitoring challenges, basic SCADA connectivity and monitoring systems are being replaced by modern, more flexible methods. While SCADA is effective for managing and gathering data, it is also challenging to customize, generates significant network traffic through wireless connections, and does not incorporate intelligence without add-on analysis software. SCADA systems are best suited for large facilities that only require local monitoring.

In lieu of traditional SCADA systems, artificial intelligence (AI) and machine learning (ML) data analysis tools have the ability for customization of specific solutions at the local level. Advantech, leading provider of Industrial Internet of Things (IIoT) and automation hardware, regularly collaborates with software vendors to offer ideal alternatives to traditional monitoring and management methods. Advantech and its partners offer non-intrusive solutions that provide more functionality than older systems—all at a much lower cost.

Advantech and Prescient Designer

To achieve a common system view across all lift stations, Advantech intelligent edge computers easily integrate and run AI/ML software developed and deployed by Prescient. By utilizing Advantech’s powerful, yet cost-effective, IIoT edge gateways with local AI/ML algorithms, end users can enable efficient management of remote lift stations. Specifically, Prescient Designer empowers users to acquire, cleanse, transform, and contextualize edge data.

Prescient Designer is a SaaS platform that enables customers to build enterprise-class and distributed data flows more easily and allows for streamlined deployment to thousands of edge gateways. Prescient Designer helps deliver high quality, consistent data in real-time with elasticity and scalability. The solution has a strong open ecosystem, utilizing Node-RED for building and customizing dashboards and supporting dozens of edge devices.

Combined with Advantech hardware, the Prescient Designer solution can achieve the following system benefits:

- Decrease of wireless traffic

- More intelligence at the edge

- Easy implementation of quick updates

- Options for local dashboards or cloud-based, remote dashboards

- Data analyzation at the edge or in the cloud seamlessly, resulting in increased intelligence in capacity management, predictive maintenance, real-time monitoring, etc.

In addition to liquid levels and pump status, new systems with industrial sensors can monitor additional parameters, including pH levels, flow, and more. Maintenance personnel have the ability to remotely update, troubleshoot, and capture diagnostics from intelligent lift station controls. Cloud-based services that manage the connectivity also reduce the need for expensive infrastructure for integration into existing networks.

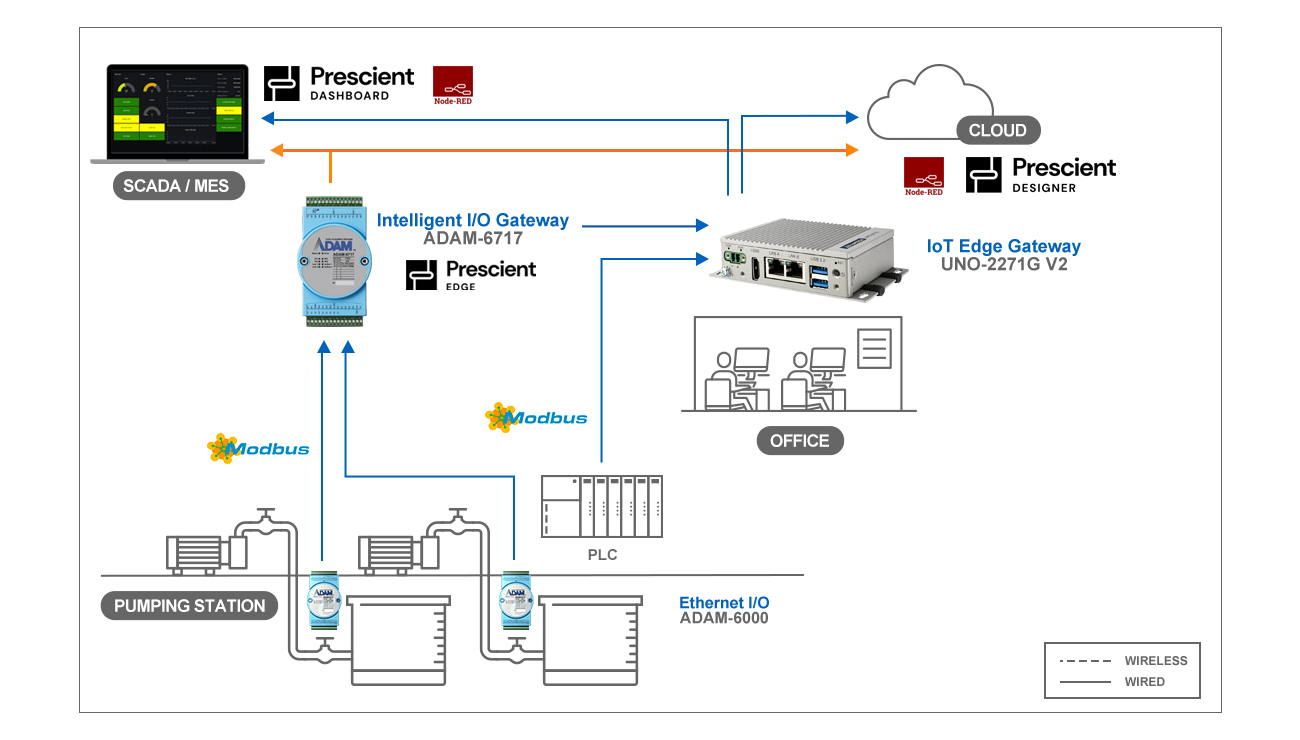

Solution Architecture

Quickly Design and Deploy Solutions

With the latest in industrial edge technology and cloud-based applications, solutions partners and integrators can quickly design and deploy custom information for each municipality. Critical events, such as system alarms, are immediately managed and communicated. If additional information is required, the system can be customized on the fly.

Monitoring is non-invasive and is as simple as installing an Advantech gateway and ADAM series module, then clamping current sensors to pump power wires. Then, users can measure the current each pump is drawing in real time. With this simple setup, along with application software, users can determine the following:

- Current drawn by each pump

- Run time for each pump

- Load on each pump

- Locked rotor failure of either pump

- Broken impeller or dry running of either pump

With the addition of floats or level sensors, the application can extend the functionality to more sophisticated readings, or even replace PLCs and control the station completely.

Advantech Hardware Integration

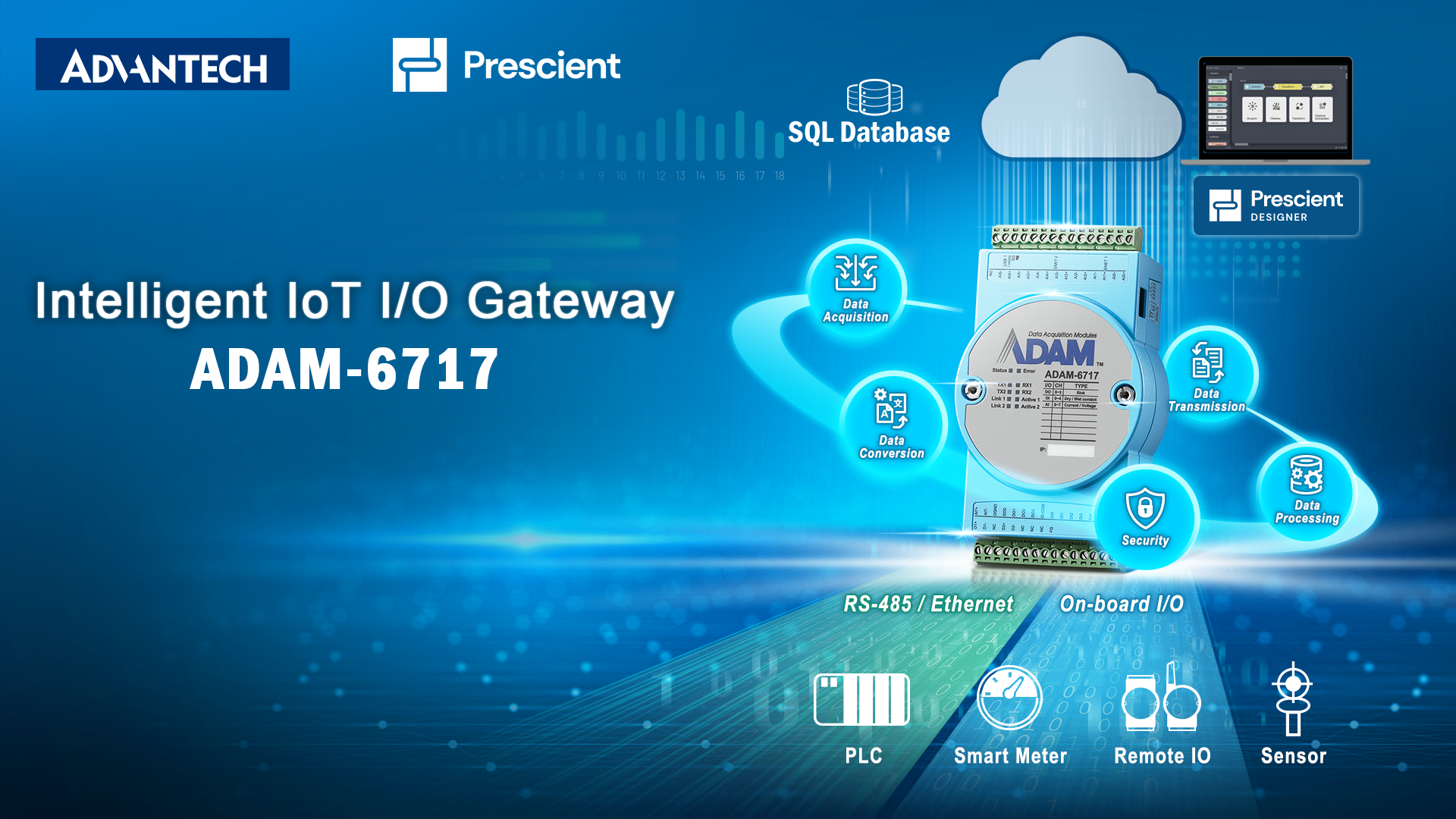

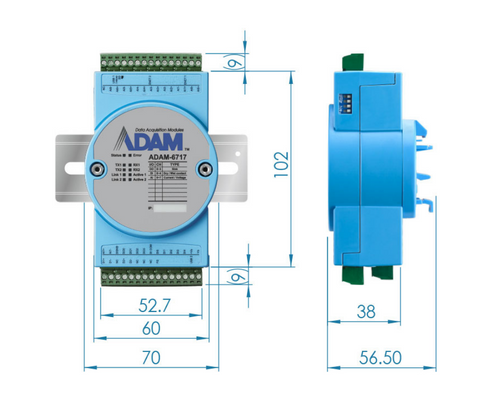

Prescient Designer runs on the cloud with Prescient Edge on Advantech’s ADAM-6717 intelligent gateway. The ADAM-6700 series offers compact, intelligent gateways for integrated solutions that are capable of performing multiple tasks at the edge. Unlike many competitors, the ADAM-6700 series is equipped with a range of I/O for comprehensive data acquisition functionality.

To operate effectively in an IoT capacity, I/O gateways must connect to on premise and cloud-based software platforms to leverage data and generate insights. Sending data between these platforms and field devices quickly, efficiently, and securely remains a challenge, especially when the Internet is involved.

The ADAM-6700 series provides these capabilities and more with open-source tools so users can easily load community-built samples and applications, saving hours of development time. These modules run on a Linux-based open platform, enabling the addition of JavaScript and C programs for advanced applications.

Compared to wired systems, the ADAM-6700 device’s wireless connectivity accessory options make data exchange simple. With a space-saving physical profile and low barrier to entry from a programming perspective, these all-in-one intelligent gateways significantly reduce commissioning and operational costs, empowering a multitude of plant personnel to configure and manage highly connected I/O systems.

The Hardware

Contact Us to Schedule a Demo

Reach out to our team at ANA.Water@advantech.com to learn more or schedule a demo.

-25/ADAM-6700E_Front-left_Square20201130134145.jpg)

-25/UNO-2271G-V220240124140441.png)

/ADAM-6717_03_B20190731125441.jpg)