-

Productos

Placas Integradas & Servicios Design-in

- Application Focus Embedded Solutions

- Box PCs Integradas y Sin Ventilador

- Computadoras en Módulos

- Embedded IoT Solutions

- Embedded PCs

- Industrial Wireless Solutions

- Módulos Integrados

- Placas Base de Uso Industrial

- Plataformas Informáticas RISC

- Señalización Digital

- Single Board Computers & MI/O Extension

- Software Integrado

- Soluciones de Visualización para Uso Industrial

- Soluciones para Plataformas de Juego

- Wireless ePaper Display Solutions

Networks & Communications

- Industrial, Telecom and Cloud Servers

- Network Interface & Acceleration Cards

- Network Security Appliances

- SD-WAN & uCPE Platforms

- WISE-STACK Private Cloud

Applied Computing (Design & Manufacturing Service)

Automatización Industrial

- Adquisición de Datos (DAQ) y Control

- Automatización de Computadores Embebidos

- Controladores de Automatización

- Gateways & Remote Terminal Units (RTUs)

- Interfaces hombre-máquina

- Módulos de E/S remotas

- Panel PCs

- Potencia y Energía

- Solución de Clase I, División 2

- Soluciones Certificado

- WebAccess+ Solutions

- Wireless I/O & Sensors

Intelligent Connectivity

- Cellular Routers and Gateways

- Industrial Media Converters

- Industrial Protocol Gateways

- Intelligent Connectivity Software

- Serial / USB Communications

- Servidores de Dispositivos Seriales

- Soluciones para Ethernet Industrial

- Wireless Industrial

Plataformas de Procesamiento DSP

- Adquisición y Codificación de Vídeo

- Advanced Video Appliances

- Procesamiento Digital de Señal Multi-Core

- Video Surveillance Platform

Sistemas Inteligentes

Informática Médica

- Carros de Enfermería Computarizados

- Computadoras Médicas

- Pantallas Médicas

- Sistemas Inteligentes de Energía

- Terminales de Info-Entretenimiento para Cuidado de Salud

Logística Digital

- Computación Móvil de Uso Industrial

- Computadoras Portátiles

- Environmental Sensing & Cold Chain Solutions

Retail Inteligente & Hospitalidad

- iCity Service & iRetail Solution

- POS & Tablets

- Señal Digital Interactivo

- Terminales de Punto de Servicio

Industrial Mounting (Stands/Arms/Workstations)

- Soluciones

- Servicios

-

Socios

Business Alliance Partner

- Soporte

- Corporativo

- Contactarnos

Registro de MyAdvantech

MyAdvantech es un portal personalizado para clientes de Advantech. Al registrarse como un miembro de Advantech, puede recibir las últimas noticias sobre productos, webinar y ofertas especiales en eStore.

Inscríbase hoy para obtener acceso rápido a la información de su cuenta.

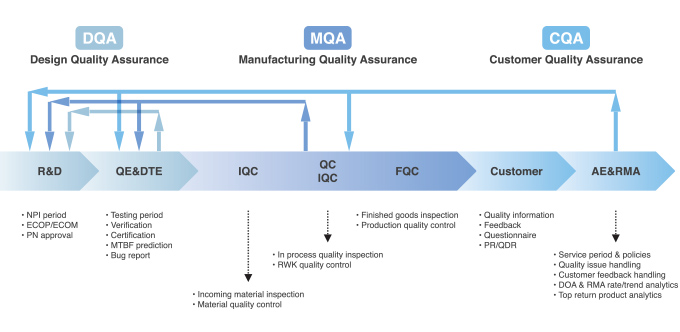

Design To Order Services

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||