Edge Solutions for Smart Monitoring of HVAC Manufacturing

24/12/2021

Abstract:

To build efficient HVAC systems, Daikin India wanted to implement intelligent solutions that support remote data aquisition for a cost-effective and sustainable means of monitoring the manufacturing and subassembly of HVAC systems.

Partner: iTG | Region: India

Introduction

HVAC systems regulate airflow, heat, ventilation, and air conditioning in homes, office buildings, and even vehicles. Essentially, HVAC systems are key mechanical solutions developed for ensuring thermal comfort and managing air quality in buildings.

To build efficient HVAC systems, expert knowledge of production equipment and strictly controlled processes are required. For this reason, monitoring the HVAC manufacturing process, collecting equipment data, and analyzing production operations is important. However, implementing a robust network infrastructure capable of adequately monitoring the HVAC manufacturing process can be both challenging and costly. According, many manufacturers are looking to implement intelligent solutions and advanced technologies that support remote data aquisition for a cost-effective and sustainable means of monitoring the manufacturing and subassembly of HVAC systems.

System Requirements

This project involved conceptualizing a smart monitoring and management solution for Daikin India, a subsidiary of Daikin Industries Ltd. and leading HVAC solutions provider in India. More specifically, Daikin India produces a wide range of energy-efficient air conditioning systems for residential, commercial, and industrial buildings.

In order to optimize energy efficiency and productivity at its factories, Daikin India wanted to implement an equipment monitoring and data collection solution. However, because the HVAC subassembly lines featured numerous programmable logic controllers (PLCs), the available installation space and network capabilities were limited. Therefore, the company needed a compact yet versatile solution for acquiring and visualizing production data without high networking/infrastructure costs. Moreover, to facilitate equipment monitoring and operational optimization, Daikin India needed a system with the following capabilities/specifications:

- Supports smart real-time monitoring of HVAC subassembly lines

- Enables seamless acquisition and visualization of equipment data

- Minimizes and streamlines data transmissions

- Configurable PLC I/O data collection flexibility

- Reliable industrial-grade hardware

Solution Description

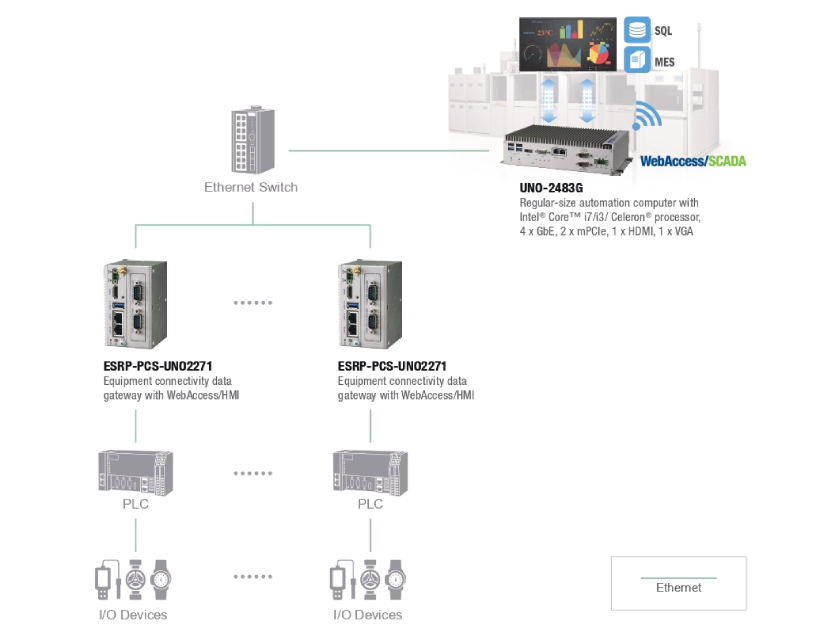

The solution provided by Advantech comprised its ESRP-PCS-UNO2271 equipment connectivity data gateway, which supports more than 400 PLC communication drivers and self-defined data conversion protocols. Furthermore, the ESRP-PCS-UNO2271 gateway was pre-installed with Advantech’s WebAccess/HMI software package to enable integrated development and data visualization for real-time monitoring.

The ESRP-PCS-UNO2271 gateway is also used to gather machine data from PLCs via I/O devices. The provision of comprehensive I/O interface support allows the gateway to be easily expanded and the uplink/downlink connectivity optimized. After collection, all data is transmitted to the UNO-2483G automation computer, which serves as the platform for Advantech’s WebAccess/SCADA software package.

This solution would allow the company to configure the Modbus/TCP protocols dynamically, integrate PLC I/O data, and store collected data on a database server for real-time visualization. Data can then be displayed on a dashboard as dynamic graphs and historical trends to facilitate analysis and operational optimization. The dashboard can also be used to review event alarm notifications and adjust set-point and status data.

Products Implemented

- ESRP-PCS-UNO2271 equipment connectivity data gateway

- UNO-2483G automation computer with Intel® Core™ i7/i3/Celeron® processor, 4 x GbE, 2 x mPCIe, and 1 x HDMI/VGA

- WebAccess/SCADA software package with 5000 tags

System Diagram

Why Advantech

Advantech’s smart monitoring solution satisfied the company’s requirements by enabling data collection and real-time visualization for intelligent equipment monitoring and management. The solution consisted of Advantech’s ESRP-PCS-UNO2271 data gateway, UNO-2483G automation computer, and WebAccess/SCADA software package.

Overall, the solution was space efficient, sustainable, and relatively cost-effective and reliable for monitoring HVAC manufacturing and subassembly. By using the WebAccess/SCADA software to collect data for analysis machine monitoring, Daikin India was able to improve machine efficiency, stability, and scalability while ensuring optimal productivity.

/WebAccess.b20180426164007.jpg)