Electric Vehicle Motor and Control Test System

08/10/2024

Project Introduction

The electric motor is a core component of new electric vehicles, significantly influencing their primary performance. As a replacement for traditional internal combustion engines and generators, it serves as the main driving mechanism. The motor's characteristics determine key performance indicators such as climbing ability, acceleration, and maximum speed, directly impacting the vehicle's dynamic performance, efficiency, and comfort. Innovations like flat wire motors and distributed drive systems with multiple motors allow electric vehicles to achieve advanced functionalities, such as lateral movement, on-the-spot turning, water drifting, and single-wheel tire blowout protection.

System Requirements

The motor control testing system requirements are as follows:

- Measure torque sensor signals with a strain gauge.

- Connect the motor encoder output (e.g., Phase A) to the frequency unit for rotational speed measurement.

- Use the analog unit and differential probes to measure three-phase inverter voltage.

- Measure three-phase current with the current unit and current sensor.

- Calculate motor power, efficiency, and inverter output power post- measurement using high-speed waveform processing, displaying results with the X-Y function.

- Specify the X-Y range for synthesis. For motor waveform changes from start to stop, select any position for X-Y display.

Project Implementation

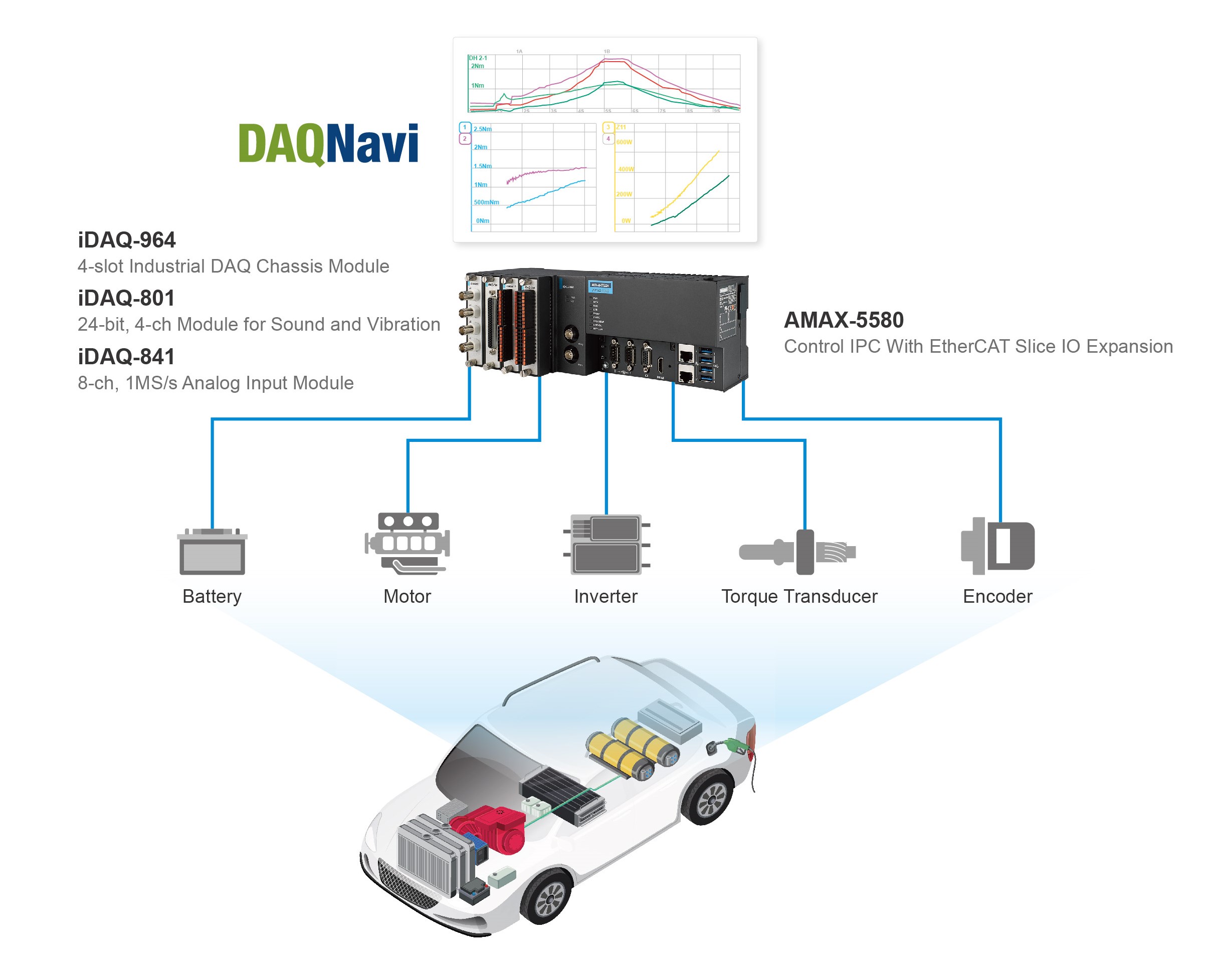

- AMAX-5580: Intel® Core™ i7/i5/Celeron® Control IPC With EtherCAT Slice IO Expansion

- iDAQ-964: 4-slot Industrial DAQ Chassis Module for AMAX-5000

- iDAQ-801: 256kS/s/ch, 24-bit, 4-ch iDAQ Module for Sound and Vibration

- iDAQ-841: 8-ch, 16-bit, 1MS/s/ch Analog Input iDAQ Module

- DAQNavi: DAQNavi is a data acquisition software to enable edge intelligence for your DAQ devices

System Description

The system adopts Advantech’s modular DAQ, iDAQ Series. iDAQ offers a variety of I/O modules including iDAQ-801 24-bit high-resolution dynamic signal acquisition for vibration measurement, and iDAQ-841, 1 MS/s ultra-high sampling rate that fully captures transmission operating parameters. In addition, AMAX-5580 with iDAQ-964 is used to output the control parameters for gearbox loading, shifting, and other operations. Meanwhile, the DAQNavi/SDK configuration software can perform data logging and real-time monitoring on the operations of the entire test system, and can perform automatic alarm and analyses if faults are encountered.

System Diagram

Conclusion

The electric motor is pivotal for electric vehicles, influencing performance metrics like acceleration, climbing ability, and speed. Innovations such as flat wire motors and distributed drive systems enhance functionalities, including lateral movement and single-wheel blowout protection. Advantech's modular iDAQ series, featuring the iDAQ-801 for vibration measurement and iDAQ-841 for high-speed sampling, ensures precise data acquisition. The AMAX-5580 with iDAQ-964 outputs control parameters, while the DAQNavi/SDK software facilitates real-time monitoring and automatic fault analysis. This comprehensive system enhances the efficiency, performance, and safety of electric vehicles.

.jpg)