Minimizing Defects with a Cold Chain Monitoring and Tracking Solution for Semiconductor Manufacturing

2022/7/28

Introduction

A global semiconductor foundry that makes chips

for other companies required a solution to control the quality of photoresist

during logistics. The customer’s original system did not provide real-time

status reports on key materials, resulting in serious manufacturing defects due

to unforeseen problems with the quality of the manufacturing process, leading

to huge losses. To overcome these problems, Advantech Design and Manufacturing

Service provided a compact cold chain solution that enabled real-time

monitoring and analysis of the temperature and humidity conditions affecting

key materials.

The impact of low-quality photoresist

Maintaining photoresist quality is important in

semiconductor manufacturing because low-quality photoresist interrupts the production

process, and this has a considerable impact on business operations and profits across

the entire semiconductor industry. The proper storage of the photoresist

solution is thus critical to ensuring the quality of subsequent processes, as it

ensures that production runs smoothly and product quality is high. This is why

the real-time monitoring and analysis of the status of key materials in transit

is critical.

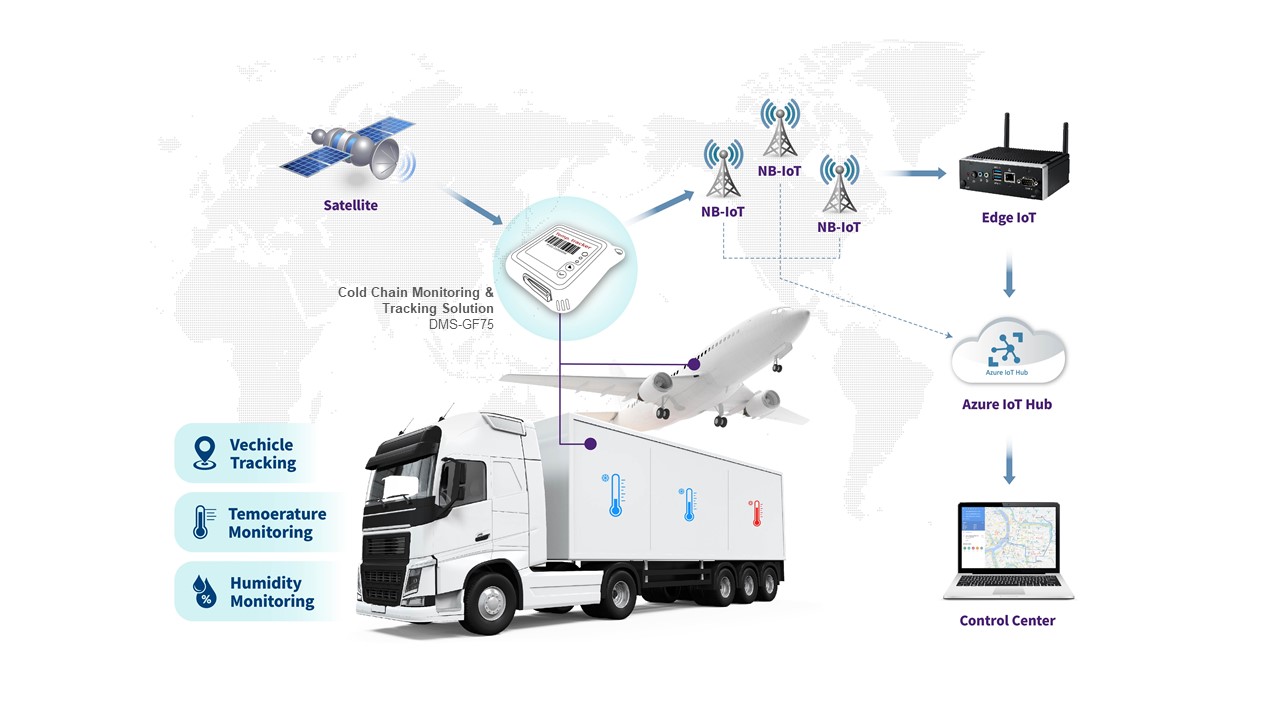

Cold chain monitoring and tracking from the edge to the cloud

The present case required an open

interconnection platform to monitor of the status of photoresist liquid. Built

on Azure IoT Edge technology, Advantech’s proposed solution provided the

customer with customized embedded computing technology designed specifically

for cold chain monitoring and tracking from the edge to the cloud. Critical

data in this case were temperature, humidity, battery life, gas, air pressure,

location, and vibration data. These are stored locally in a log file that is

uploaded to Azure via NB-IoT and MQTT, the timing of which is triggered by GPS/BeiDou/GLONASS

data, thus making it more reliable when uploading material status information

at key points during transportation.

This required a tracking device to be packed

into each photoresist package, which adds to shipping costs. As such, a

lightweight design was a critical consideration. Advantech’s proposed NB-IoT

based cold chain sensor was not only compact and lightweight (>100 g;

dimensions: 75 × 75 × 23 mm), but it extended the battery lifetime of the

previous system from 14 to 30 days.

Real-time monitoring reduces defects and boosts production

Advantech’s extensive industrial expertise and comprehensive support services meant that they were able to offer customized services combined with advanced technology to effectively reduce the solution development time and costs. The proposed solution enabled real-time monitoring analysis of key materials, and this has contributed significantly to reducing the risk of material failure, which in turn has boosted production yield.

System Diagram

.png)